How-To: Mastering the 4-in-1 Bucket: Tips for Grading, Dozing, and Clamping

The 4-in-1 bucket is frequently referred to as the “Swiss Army Knife” of construction and landscaping. It is a single attachment that when skilfully used by skid steer operators can substitute an entire fleet of specialized tools. With this one attachment, you can go from heavy excavation to delicate site finishing without even needing to get out of the cab.

However, merely having a 4-in-1 bucket is not sufficient; you must comprehend the subtleties of its hydraulic capabilities if you want to fully leverage your investment.

Regardless of whether you are a seasoned professional or a new owner, mastering the techniques for grading, dozing, and clamping that the pros employ will be a sure way of enhancing your productivity and quality of the finish.

Through incorporating four separate actions—digging, grabbing, dozing, and leveling—in a single sturdy frame, this tool gives you superior efficiency to handle complicated clearing of land, agricultural, and urban infrastructure projects at a level hardly ever matched by others.

This article will take you step by step through the workings of each operation, coupled with expert advice, so that you can master your 4-in-1 bucket like a pro in no time.

The Versatility of the 4-in-1 Bucket: An Overview

Knowing what makes the 4-in-1 bucket such a must-have tool on your worksite is a good place to start before concentrating on specific techniques in detail. Basically, a 4-in-1 bucket offers you a huge set of options. To begin with, a 4-in-1 bucket is one that has been designed with a split-bottom, operated by two robust heavy-duty hydraulic cylinders.

This enables the operator to open the “jaws” of the bucket and do some of the work that you would typically associate with a grapple, a dozer blade, or a box scraper.” It is like having four tools in one:

- Multi-Purpose Functionality: Easily change from a standard loader bucket, a grapple for unlocking debris, a dozer blade for spreading, and a scraper for finishing.

- Time and Cost Efficiency: Say goodbye to time lost when changing compliance; also, you no longer have to take several heavy equipment to a single hire site.

- Precision Control: Closely regulate the hydraulic movement to meter out materials such as gravel or mulch in a way that is much more accurate than a normal dump.

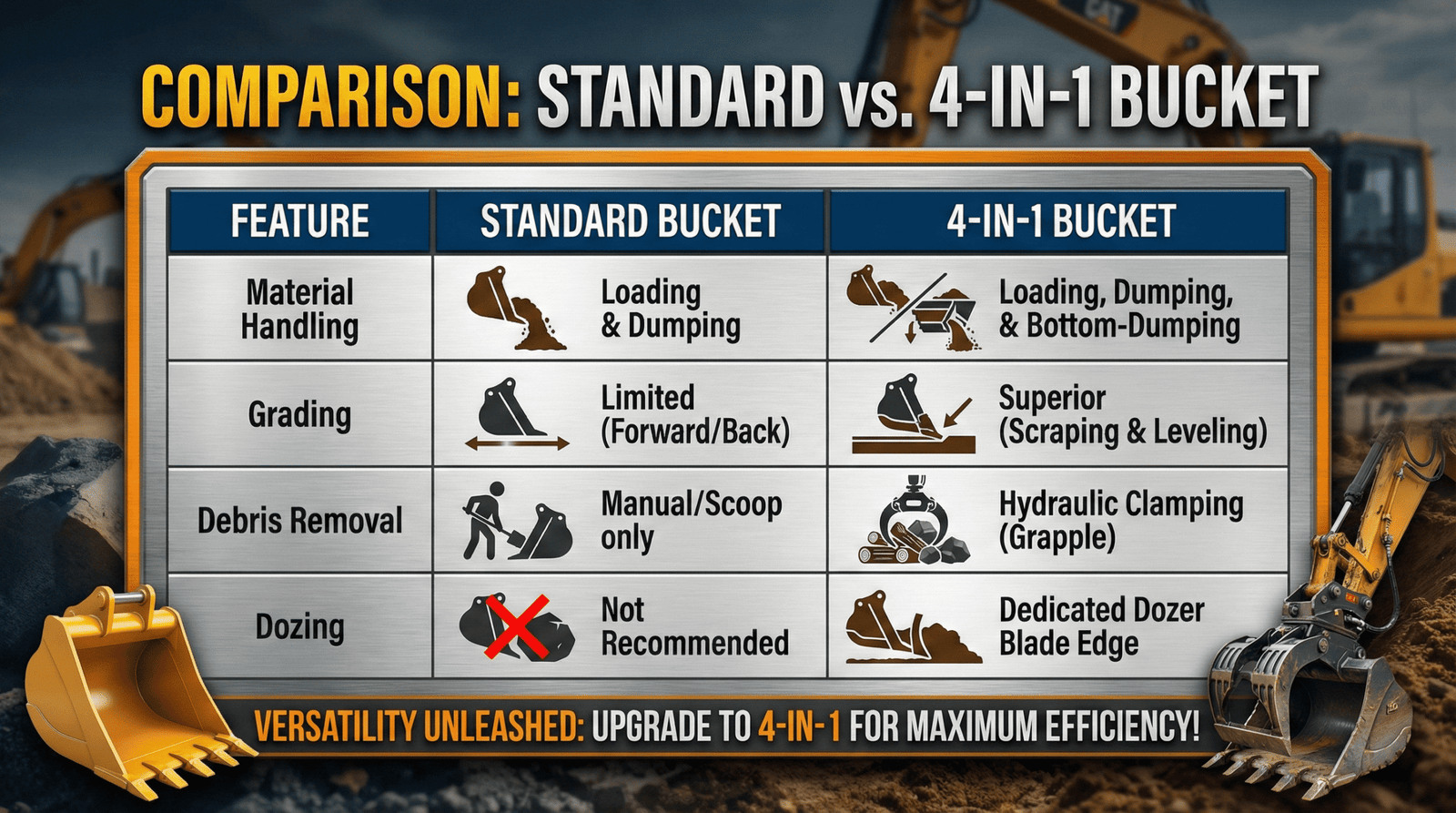

Table: Comparison 4-in-1 Bucket Vs Standard Bucket

| Feature | Standard Bucket | 4-in-1 Bucket |

| Material Handling | Loading & Dumping | Loading, Dumping, & Bottom-Dumping |

| Grading | Limited (Forward/Back) | Superior (Scraping & Leveling) |

| Debris Removal | Manual/Scoop only | Hydraulic Clamping (Grapple) |

| Dozing | Not Recommended | Dedicated Dozer Blade Edge |

4-in-1 Bucket and Standard bucket comparison

Mastering the Dozing Function: Pushing with Power

The pushing or dozing with the help of a 4-in-1 bucket is done by separating the bucket and utilizing the rear as a blade. This way, your skid steer can be considered as a small bulldozer capable of pushing soil, sand, or gravel in huge quantities.

The 4-in-1 bucket with all its rugged construction and reinforced cutting edges is quite capable of handling the lateral stresses of dozing without any compromise to the frame.

- Positioning the Blade: When the bucket is opened up and slightly tilted forward, the rear cutting edge becomes visible. This cutting edge is what will keep the blade attached to the ground and move the material forward.

- Maintaining Traction: Keep your skid steer at around 75% throttle to achieve the best results. This is enough power for your machine to make slight hydraulic modifications and still grip well to the ground with the tires or tracks.

- Overlapping Passes: When working on a large site, it is advised that you overlap each pass by 20%. This prevents the formation of the windrow, by the sides of the 4-in-1 bucket.

Professional Grading and Leveling Techniques

Grading is the kind of activity that not only demands a certain level of skill but also the person doing it has to be a professional. To be able to grade your site with precision using a 4-in-1 bucket you have to perform a “back-dragging” and “scraping” operation.

You can cut down peaks and fill up valleys by using the internal edges of the 4-in-1 bucket hence achieving the desired perfection of the surface tailored to your landscaping or foundation requirements.

- The Float Mode Advantage: Use the float mode of your machine to attach the 4-in-1 bucket to the ground when back-dragging. Because of this, the bucket will not apply any additional pressure which might cause gouging to the surface or floor.

- Visualizing the Edge: Along with skill, finish grading requires a good eye. The 4-in-1 bucket should be two inches wider at least than the width of your machine’s tires or tracks so that the turning moment can be controlled and the freshly graded area is not compacted by the wheels.

- Controlling the Slope: When the grading operation is done next to the veranda or walkway, the 4-in-1 bucket should always be angled in such a way that there is a slight slope (at least 6 inches within the first 10 feet) leading away from the structure foundation to avoid water pooling.

Advanced Clamping and Grabbing for Debris Removal

The “grapple” is the mode that the 4-in-1 bucket is flexing for where it is most frequently seen. This tool lets you clamp down on the item of irregular shape by utilizing the hydraulic cylinders such as tree limbs, chunks of concrete, or demolition debris.

This feature makes the 4-in-1 bucket highly valuable for the settling of the site and clearing of the land than a simple standard bucket that would just let the material roll out.

- Securing the Load: It is essential to close the jaws around the parts of the debris before lifting the waste. Hence, make sure that the bucket is completely open and the front edge is touching the ground, then drive forward a bit to “bite” the object and consequently close the jaws by means of hydraulic controls.

- Bottom-Dumping Precision: There is no need to dump by tilting the whole attachment if you choose to open the bottom of the 4-in-1 bucket only. This method is advantageous, especially when it comes to loading high-sided dump trucks or spreading mulch in the garden.

- Safety First: At any time, be sure that the people on-site are far away from the “pinch points” of the bucket. The force involved is so great that it can crush heavy materials very easily—hence it is important that nobody is caught up in it.

Maintenance Tips for Longevity

With a view to having your 4-in-1 bucket working efficiently all the time, maintenance has to be performed continually. This attachment works on the principle of parts in motion and hydraulic pressure. Hence it is inevitably depending on the consumables.

When you delay maintaining your 4-in-1 bucket, you are in fact bringing it closer to its end of life. Thus, you should be very keen on the maintenance schedule in order to continue having the benefit of the 4-in-1 bucket for years.

- Grease Pivot Points: With hinges and pines on a hydraulic cylinder that are constantly exposed to friction. Grease them daily so that they last longer and the operation of opening and closing the bucket is smoother and almost without effort.

- Inspect Cutting Edges: The 4-in-1 bucket has a number of cutting edges. (It includes separate front, rear, and internal edges). Do a regular check-up for wear and if the bolt-on edges are close to wearing down, replace them.

- Hydraulic Hose Management: Check to see that the hoses are properly routed and covered. A damaged or leaking hose will instantly turn the hydraulic-powered 4-in-1 bucket into a useless attachment and the contamination of the hydraulic system might cost you a lot cheaper.

FAQs: Skid Steer Attachment 4-in-1 Bucket

Is a 4-in-1 bucket better than a standard skid steer bucket?

Of course, the answer is yes for their versatility. A standard bucket is lighter and better for pure volume loading while a 4-in-1 bucket can do more than that. With it, you can doze, grade and grasp debris without changing attachments thus, saving a lot of time on complex projects.

Can I use a 4-in-1 bucket for heavy digging?

Yes, certainly. A good quality 4-in-1 bucket can perform traditional digging tasks efficiently because of its sturdy construction. The only downside is, it is heavier than a standard bucket and that may cause your machine’s rated operating capacity (ROC) to be a bit lower than before.

How do I choose the right size 4-in-1 bucket for my skid steer?

Your 4-in-1 bucket must be somewhat wider (approximately 2 inches) than your skid steer’s tires or tracks width. This will ensure that you can grade and doze without your machine running over the material that you are trying to level.

Does a 4-in-1 bucket require high-flow hydraulics?

Most 4-in-1 bucket attachments work well with standard auxiliary hydraulic flow. In general, high-flow is meant for power-thirsty attachments such as mulchers or cold planers and not for regular 4-in-1 buckets.

What are the common mistakes when using a 4-in-1 bucket for grading?

When operators go too far with downward pressure, it results in the bucket “going in” and that way, it makes holes. The key to a smooth finish is to use “float” mode and make tiny, gradual changes to the angle of the bucket.

Can a 4-in-1 bucket replace a dedicated grapple?

Yes, for general cleanups. A dedicated skeleton grapple, however, is more desirable if large amounts of brush or logs are involved; better visibility and screened material drainage will be achieved.

How much maintenance does a 4-in-1 bucket need?

Since the 4-in-1 bucket has moving jaws, it requires more maintenance than a simple one. You will have to grease the pivot points daily and at regular intervals, and also look at the hydraulic cylinders and hoses for any leakages or damages.