The Ultimate Guide to Skid Steer Cold Weather Operation & Engine Pre-Heating

When a winter storm moves in with snow and ice, a skid loader becomes a construction workers, agriculturalists, and landscapers who rely on the compacity hardware like the TYPHON STOMP mini skid steer loader throughout the year, proper winterization is not only a recommendation—it is the essentially the difference between a costly downtime and a reliable productivity. Operating a skid steer successfully under sub-zero conditions needs a thorough approach that covers the fluids, fuel, and also the machine’s electrical and hydraulic parts. Knowing and using the concepts of Skid Steer Cold Weather Operation will keep your investment safe and will give you the assurance that your machine can work even when the temperature is extremely low.

Mastering the Art of Engine Pre-Heating

The core of any skid steer, most of all a diesel one, is the part that definitely struggles the most when the cold comes. Cold dense air makes compression difficult, at the same time cold engine oil gets thicker, thus it creates a strong resistance and calls for more power from the battery. So, Engine Pre-Heating done in an efficient way is the most vital part of the whole work if one wants to avoid a severe wear of the engine and to be able to make a successful start on a freezing morning. Just turning the ignition key without the pre-heating step will surely end up with a battery that is dead and a starter that is broken.

- Make good use of Glow plugs and Engine Block Heaters: Generally a glow plug (directly heats the combustion chambers) or a block heater (warms the coolant and engine block) comes as an accessory to the latest models of skid steers. In case of very severe cold a block heater becomes indispensable. So, as an example, when one is going to work during the night and will be back the next morning, plug your machine in 4 to 6 hours before your shift if that is the temperature dropping below zero, a normal recommendation of 4 to 6 hours is being made by most workers,-to let the heat slowly rise to the engine core making it much easier to achieve the necessary compression for ignition.

- Never overuse the Starting Fluid (ether): It is simple to get a hold of but in case of excessive or improper use of starting fluid (ether) it could become highly detrimental and, at the same time, very quickly could lead to immediate damage such as broken piston rings or head gasket failure, especially in engines with automatic glow plug systems. Instructions should always be checked in the operator’s manual and if fluid must be used then it should be injected only in a situation when the engine is actively cranking and never near a glow plug that is already active since that can cause an explosive intake fire.

- Get the Engine and Hydraulics Running: After a cold start and before heavy work, you should keep the engine running at a low RPM until it warms up. Letting it warm up slowly will save the engine from blow thermal shock. In addition, very gently raising and lowering the hydraulic control will let the older, thicker hydraulic fluid get warm and circulate through the system before you put the pumps and cylinders under a heavy load.

Fluid Dynamics: The Cold-Weather Viscosity Swap

Fluids are what keep your little earth-mover going, but their thickness is a big problem when the temperature drops. What is a great solution in the hot summer will become a thick, abrasive sludge in the cold, which will drastically increase friction, decrease fuel efficiency, and cause internal parts to wear at a faster pace. Proper Skid Steer Winterization entails the use of low-viscosity, cold-weather-rated fluids.

- Switch to a low-viscosity engine oil: The normal summer engine oils (e.g., SAE 30 or 15W-40) are simply too thick for starting an engine in the cold. A lighter synthetic oil such as 5W-40 or 0W-40 synthetic blend is a lot better for cold areas as it is capable of keeping itself liquid at sub-zero temperatures and thus will be able to coat the parts much faster during the very first crank. That move not only lessens the load on the battery but also protects the engine from start-up wear.

- Use Cold Weather Hydraulic Fluid: Next in line is the hydraulic system that becomes the victim of the cold. Cold hydraulic fluid is the main reason for slow and less powerful attachment movements and at the same time, pump overheating. By using a specifically designed Cold Weather Hydraulic Fluid (that is usually thinner) the operation will be quicker and easier, the device will be ready for work in a short period of time, and also, it will be less probable that the cold-affected seals and hoses (which will have become brittle) get damaged.

- Check Antifreeze and Coolant Levels: Make sure that the mixture of the engine coolant is enough to keep it from freezing. What is absolutely necessary for the mixture of antifreeze and distilled water to be is that it is balanced, as too little water will lessen the effectiveness of the anti-freeze while too much water will lower the boiling point. Check the ratio with a hydrometer, and make sure that the mixture rating surpasses the lowest temperature that you will be operating in.

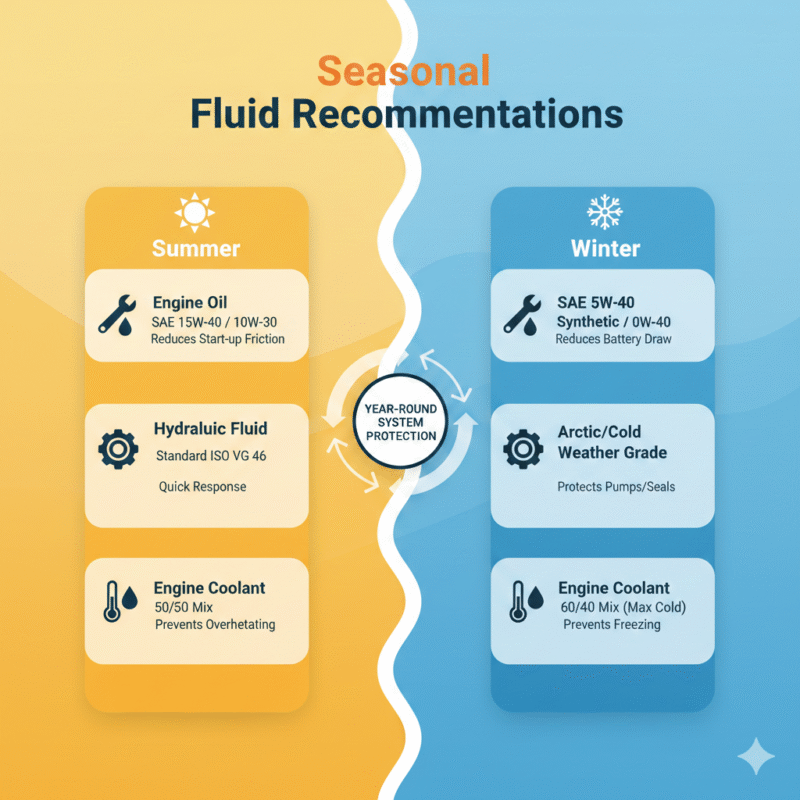

One can get a general idea (always follow the specific OEM manual for the machine) of necessary oil changes based on temperature to visualize the information:

| Fluid Type | Summer Temperature Range (Above 32°F / 0°C) | Winter Temperature Range (Below 0°F / -18°C) | Purpose |

| Engine Oil | SAE 15W-40 or 10W-30 | SAE 5W-40 Synthetic or 0W-40 | Reduces start-up friction and battery draw. |

| Hydraulic Fluid | Standard ISO VG 46 | Arctic/Cold Weather Grade (e.g., 0W-20) | Ensures quick response and protects pumps/seals. |

| Engine Coolant | 50/50 Mix | 60/40 Mix (Max Cold Protection) | Prevents freezing and overheating; raises the system’s freeze point. |

Skid Steer Cold Weather Operation & Engine Pre-Heating TF

Battling the Freeze: Fuel and Battery Health

Once the temperature goes down to freezing or below, the battery will lose reserve power and diesel fuel will start to gel. What follows is a deadly combination that can bring any equipment operator to his knees. A skid steer battery with Cold Cranking Amps (CCA) being kept in good condition as well as fuel flowing freely are the two must-do things that have to be there if one wants to be ready for cold weather.

- Stop diesel fuel from gelling: Regular No. 2 diesel fuel is full of paraffin wax that when exposed to cold temperature will crystallize (gel) thus clogging filters and things will eventually come to a complete standstill. To fight back against the gelling of diesel fuel, one should move to a winterized blend (No. 1-D diesel) or allow the use of the highest quality anti-gel fuel additives. It is very important to add these substances before the temperature drops and the best time to do it is when filling the tank so that it will be properly mixed.

- Deal with the water and condensation: At the end of each workday be sure to keep the fuel tank as full as possible. A completely filled tank will considerably cut down the surface area that is left inside the tank for which warm and humid air can come and condense into water droplets during the night. This water can deposit at the bottom of your tank, later it can freeze in the fuel lines, or it can mix with diesel and cause rust. Make sure you comply with the schedule for your Compact Loader Maintenance by regularly draining the fuel/water separator.

- Check and Secure the Battery: Batteries lose a large part of their capacity in cold weather and at the same time, they have to give almost double the power needed to crank the engine. There is a need for a battery load test to be done before winter comes so to be sure of the battery’s CCA. Corrosion must be removed from the terminals, and connections should be tight. To keep its core temperature, in very cold weather conditions, it is also wise to take a battery blanket or an indoor battery storage solution into consideration.

Keeping the Tracks and Tires Rolling

The part of the machine that contacts the earth is just as vulnerable to the cold as the engine is. No matter if you have a wheeled or a tracked compact loader, the performance of the undercarriage will be of great importance for traction, safety, and parts lifespan during Skid Steer Cold Weather Operation.

- Be Tire Pressure Conscious at all Times: The cold will make tire pressure fall even more and as a result, a skid steer will lessen its lift and pushing power since the ground contact is smaller. Tire pressure should be checked before the beginning of the work of each day and be restored to the manufacturer’s specified PSI if it is found to be lower, it is highly recommended, though, to do it indoors in that case in order to have a correct bead seat. If tire pressure is too low then the tire will be excessively flexible which in turn will cause you to have cracks in the winter hard rubber due to the tire getting stretched further than it should.

- Undercarriage Cleaning Daily (Especially Tracks): Daily cleaning is very important to track loaders. Snow, ice, mud, and particularly the de-icing salt that is corrosive can get trapped into the undercarriage freezing around rollers, sprockets, and idlers. This ice tightening can cause components seizure or too much tension which results in misalignment of the tracks, de-tracking, and rapid wear. Cleaning the undercarriage is performing a step towards the prevention of this type of costly damage.

- Use Winter-Ready Attachments: Skid steers just can’t do it better in winter chores than turning the standard bucket into a snowpusher and that’s not all. A sturdy snow pusher, a light snow dusting angle broom, or a powerful snow blower will cut machine time, make the job easier, and machine will strain be versus lesser. Even when freezing earth is the case, an earth auger attachment does what it is made for thereby you can set posts or make yards for houses.

Operator’s Routine and Safety

The safe and efficient work of the machine in cold weather is to a great extent dependent on the operator’s daily routine and the environment in the cab. An operator that is comfortable will be a safer and more productive one. This last check is for assuring the machine’s safety and is there to protect the person behind the controls.

Three-Step Start-up and Warm-up Method: A cold start should not be rushed at all.

- Check Plugging: Be sure that the pre-heating device is plugged in, do not start the engine until the glow plug indicator has turned off, and after the engine has been successfully started, let it run on an idle speed for 5 to 10 minutes. By doing so all the essential fluids (i.e. engine, hydraulic, and transmission) will be thinned and will also be circulated thus providing the very first lubrication layer before the system is overloaded.

- Check Rubber Parts and Seals Thoroughly: Extremely low temperatures can make the rubber seals, belts, and hydraulic hoses stiff and brittle and as a result, these can get cracked very easily if you put them under pressure. Before turning the machine on, thoroughly examine all the hoses and belts that you have. Check if any small cracks or frayed parts are present and also, if you find any such components, do not hesitate but replace them right away since the failure of a hydraulic hose and the subsequent leakage of a freezing situation can be a dangerous, costly and messy event.

- Make Cab Comfort and Visibility Your Priority: Your cab heater and defrost system must be kept in good working order at all times. Placing frozen windows and you cold cab are not only irritating but also highly risky from the safety point of view. It is advisable to check the condition of the window and door seals so that you can make sure that they are keeping the heat in and also remember to keep your windshield washer anti-freeze topped up. Considering that days during winter are shorter and at the same time visibility is mostly bad due to snow, make sure that all work lights, beacons, and safety alarms are in working order.

FAQs

Enhance your Skid Steer Cold Weather Operation skills! Our guide covers crucial insights on Engine Pre-Heating for peak performance in frigid temps with these FAQ’s.

Q: How cold is too cold to run a diesel skid steer?

A: Generally, a diesel skid steer of the standard type can perform down to 0 degrees F (minus 18 degrees C) without any extra gear. When it comes to temperatures lower than that, pre-heating is compulsory. In the very cold area (under 20 degrees F / 29 degrees C), you must use synthetic fluids, specially configured starting aids, and also keep the block heater plugged in continuously.

Q: How long should I plug in the engine block heater before starting?

A: The time of 3-4 hours is most often enough for a winter period of around zero to 30 degrees Fahrenheit. In the very cold situation (temperature below zero), it is usually considered the best method to connect the device to the power supply for the whole night, especially if it lacks a heated or naturally warm place to store.

Q: What is the risk of using summer fuel in the winter?

A: The principal risk is Diesel Fuel Gelling. The paraffin wax contained in No. 2 diesel fuel solidifies and thus, the fuel filters and lines become clogged with the crystallized material, which leads to engine shut down. Using a winter-grade (No. 1-D) diesel and anti-gel agents are the only ways to prevent this from happening.

Q: Should I idle my skid steer all night in very cold weather?

A: Long periods of idling are generally not recommended since they may cause wet stacking (a condition where unburnt fuel washes down the cylinder walls) and may also reduce the life of the engine. A well-functioning block heater together with the right choice of lubricant is more cost-effective and better for the engine.

Q: Can I use the same hydraulic fluid year-round?

A: Some fully synthetic hydraulic fluids are multi-viscosity and can be used throughout the year, but most regular fluids require the seasons to be changed. Using a low-viscosity, Cold Weather Hydraulic Fluid during the winter period will provide a better working machine and prevent the pump from being damaged at startup.

Q: How often should I check my tire pressure in the winter?

A: Tire pressures should be checked on a daily basis, right before the beginning of a work shift. The pressure in the tires can go down very much during the night because of the temperature drop. At the same time, the vehicle’s stability and lifting capacity will be affected.

Q: Why is my skid steer slow to lift and tilt when it’s cold?

A: This problem is almost certainly due to the hydraulic fluid being too viscous. The fluid is too thick to flow efficiently through the pumps and lines. The way to fix this is either to warm the system by running the engine and gently operating the control functions, or changing the fluid to a correct Arctic-grade one.