Beyond Buckets: Maximizing ROI with Specialized Forestry Mulching Skid Steer Attachments

Every construction site, farm, or large acreage begins with a vision, and more often than not, that vision is a skid steer loader. Basically, it’s the multi-tool of skid steer attachments —quick, strong, and very flexible for forestry mulching. Most users would typically think of the bucket which is the most common and hence, the go-to attachment. It digs up the ground, heaps up refuse, and fills vehicles.

However, if you want to scale your business in a real way, get higher rates, and convert overgrown land into cash quicker than you have ever done before, it’s time to consider no less than the specialized forestry mulching skid steer attachments the true profit engine in land management, site prep, and vegetation control.

It is far from just dealing with the problem of land clearance; it is about maximizing your Return on Investment (ROI) by performing the task faster, and more efficiently and with fewer follow-up tasks.

The Hidden Cost of “Traditional” Clearing

Land clearing used to be a slow, multi-step, and costly process before the advent of specialized mulchers:

- Cutting/Piling: The use of chainsaws, dozers, and excavators for cutting down trees and bundling them for burning or shredding.

- Burning/Hauling: Acquiring permits, handling the smoke, or paying steep fees to get rid of the material off-site.

- Grinding/Stumping: A separate operation for handling stumps and leftover debris, thus necessitating the use of another specialized machine.

The whole process is very demanding of the resource, time-consuming, and not so attractive environmentally. Each additional hour that you have to spend on waiting for a burn or driving the material to a landfill is actually taking away your profits.

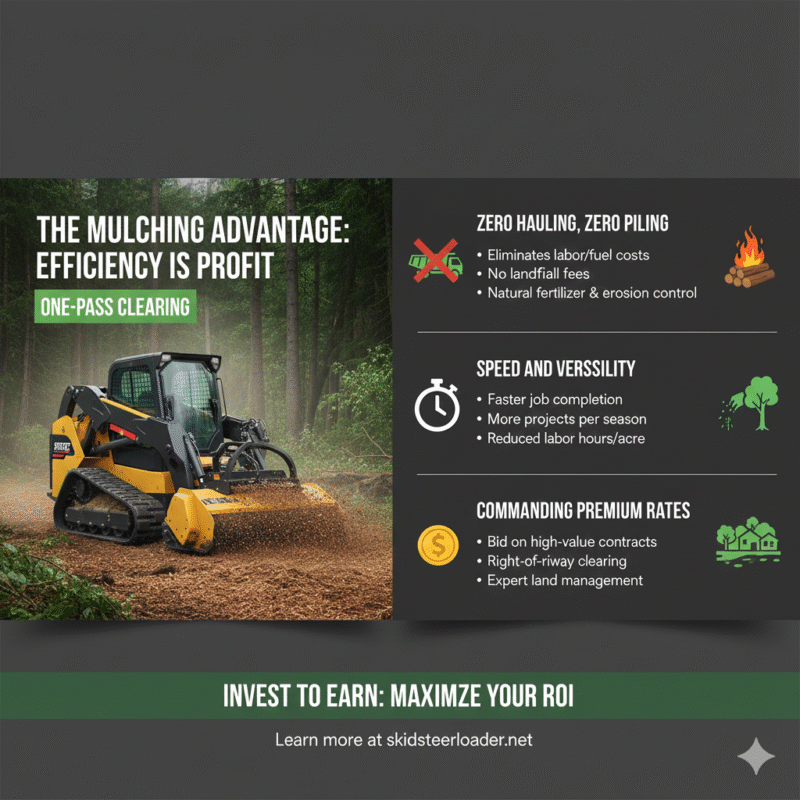

The Mulching Advantage: Efficiency is Profit

With a forestry mulcher head, you can convert your existing skid steer into a material moving machine to a powerful, tree-shredding machine in no time.

The main reason for such a great return on investment is the concept of “one-pass clearing.”

-

Zero Hauling, Zero Piling

A mulcher does not only separate—it also combines. For instance, it accepts trees, brush, and undergrowth up to a certain diameter, and it returns the whole lot in nutrient-rich wood chips and mulch, which it uses to cover the ground evenly.

Labor and fuel costs associated with the hauling of debris are eliminated by the user. The waiting time for the lifting of the burn ban is also saved apart from the money spent on the tipping of the landfill. The material remains on the site, thus serving as a natural erosion barrier and fertilizer.

-

Speed and Versatility

The amount of work that a high-flow mulcher can finish in one day of manual labor or even with the help of a dozer is probably not more than 50% of what it can do. What a skilled operator will be able to do is methodically work their way through dense vegetation, and in the end, they will have a clean surface that is flat and can be used for the next stage (planting, construction, or maintenance).

ROI Impact: The reason for job completion being quicker will be that you will be able to take on more projects during a certain period of time. Machine downtime will be less, and dual labor hours per acre will significantly decrease.

-

Commanding Premium Rates

Specialized pricing should be set for specialized work. By having a forestry mulching attachment, you will be enabled to bid on such high-value contracts which general contractors are not capable of doing i.e., right-of-way clearing, fire break construction, pipeline maintenance, and large-scale residential development prep.

- ROI Impact: You move from the submission of bids on the work of dirt moving to the submission of bids on landscape shaping which places your company as a land management expert dedicated to this field.

- The Specialized Difference: Features That Drive Performance Not every mulcher is capable of being one. To really maximize the return on investment, you need to be familiar with the technical aspects that set apart an average attachment from a high-performance, money-making asset.

Skid Steer Attachments Forestry Mulching

High-Flow Hydraulics: The Engine of Efficiency

The single most crucial element is the hydraulic system. The demands on the hydraulic system of a forestry mulcher are usually 30 gallons per minute (GPM) or more, in that case, the system not only spins the rotor but also keeps it at a high torque.

It is always better to have a high-flow skid steer and ensure that the GPM and PSI of its output correspond to the requirements of the mulcher head. A powerful attachment on a weak machine will lead to low productivity and you will be frustrated.

Rotor and Teeth Technology

The part of the machine that is directly connected to the mulcher and thus strongly influences both its speed and the quality of the cutting is the rotor.

- Fixed Carbide Teeth: Extremely durable, should be used for rocky terrain or ground with a high percentage of soil contamination. They are harder and require less frequent sharpening but may process material a little slower.

- Sharpened/Planer Teeth: Best for use on clean land with big trees. They work more efficiently and provide a finer finishing but require frequent sharpening and are vulnerable to damage by stones.

Some of the great attachments make it possible to quick and simple replacement of teeth thereby shortening the time that they have to be stopped for repair due to damage.

Structural Integrity and Safety

Besides looking for strong construction features such as heavy-duty push bars and protective safety screens, you need to consider the fact that your attachment will be put under a lot of pressure. A good publicly funded project, a well thought out mulcher head, therefore, means more time for money-making and less time for welding broken parts.

Strategic Verdict – Forestry Mulching Attachments:

Invest to Earn The clearest way to increase revenue in land management is to move beyond the bucket and to invest in a specialized forestry mulching skid steer attachment. The investment is not only worth it for the hours of labor it saves but also for the premium projects it opens the door for.

Along with the steel, what you’re really buying is speed, efficiency, and the capacity of providing a superior, environmentally friendly service that customers are ready to pay top dollar for. A serious question for an operator is not whether he can afford a specialized mulcher—rather, whether he can afford not to have one.

FAQs on Forestry Mulching Skid Steer Attachments

What is the principal difference between standard-flow and high-flow mulchers?

The difference is the hydraulic power needed. High-flow mulchers need a flow rate usually over 30 GPM and are used for professional forestry work. They produce enough speed and torque to grind large trees and dense brush. Standard-flow (about 15-25 GPM) mulchers are mainly for light brush cutting and grass mowing and should not be used for heavy-duty forestry work.

How big of a tree can a skid steer mulcher head cut?

The maximum capacity varies depending on the model, but most heavy-duty forestry mulchers can instantly process standing material with a diameter of 6 to 8 inches, and they can effectively grind larger trees by breaking them down from the top.

Are carbide teeth or sharpened (planer) teeth better for ROI?

That depends on your primary environment. Carbide teeth are more suitable for the highest ROI in rocky or less-than-ideal terrains as they are very durable and therefore downtime due to replacement is minimized. Sharpened/planer teeth can be more efficient in clean, strictly wooded areas, whereby faster processing of material and a finer finish can be achieved; however, their weakness to rocks can quickly offset their efficiency advantage.

How does mulching compare to using a dozer for land clearing?

Mulching is a finish process; dozers are bulk movers. A dozer tears out trees along with the roots and moves the waste to a place where it is piled up, thus leaving stumps and soil that has been disturbed. On the other hand, a mulcher breaks up everything that is still in place, thus making it go significantly faster and cleaner resulting in a job site that is ready for use right away with no stumps or piles of debris left over.

What is the expected maintenance for a mulching attachment?

Regular maintenance is a must. Amongst other things, it requires daily checking of the teeth for damage, assessment of belt tension (if applicable), making sure the rotor bearings are properly greased, and inspecting hydraulic hoses for leaks or wear. The most common maintenance activity is tooth replacement, and it should be included in your operational costs.

Can I use any skid steer for a forestry mulcher?

No. A high-flow (HF) skid steer, which either meets or exceeds the flow rate (GPM) and pressure (PSI) requirements of the particular mulching head, must be used. Using a standard-flow machine with a high-flow mulcher will lead to poor performance, and the attachment or the skid steer hydraulic system will be damaged.

Do I need special safety features when operating a mulcher?

Certainly. One of the safety features that must be used when operating a mulcher from a skid steer is a Polycarbonate Door/Front Shield (usually thicker than 1/2″) and the suitable cab enclosure to assist in protecting the operator from extremely high-velocity thrown debris. Safety should be treated with the utmost respect and be non-negotiable.