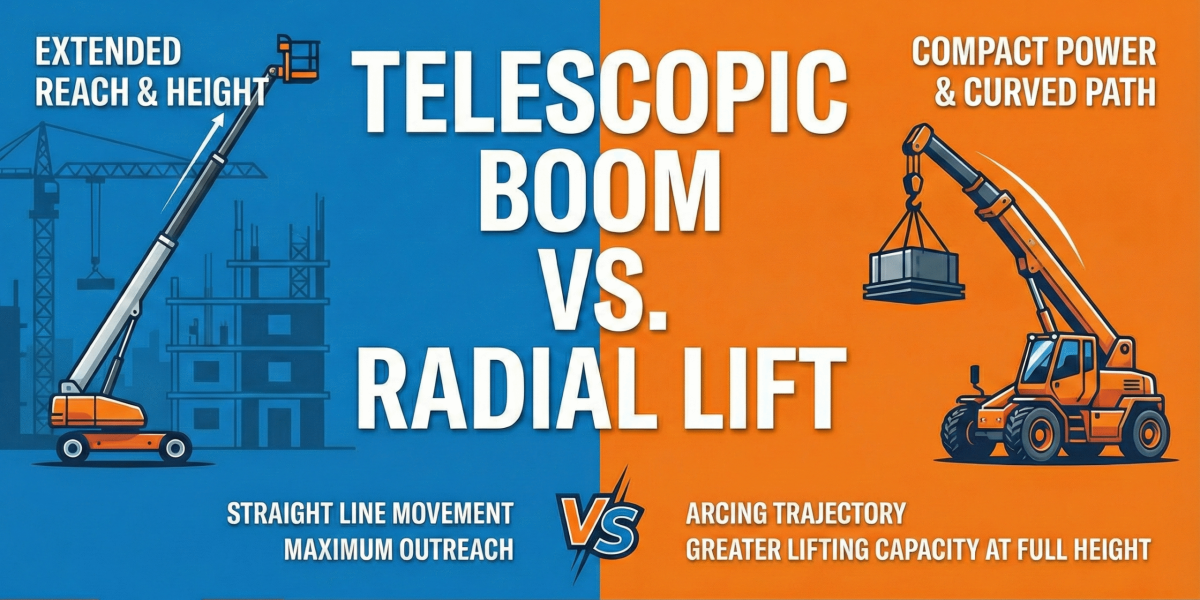

Telescopic Boom vs. Radial Lift: How to Choose the Most Suitable Skid Steer Geometry for Your Fleet

Choosing the right lifting geometry often means the difference between a smooth and efficient job or a project filled with delays and inefficiencies when overseeing a modern fleet of heavy machinery. For years, the industry standard radial lift was the go-to workhorse across the globe. Hence, the decision to choose among Telescopic Boom vs. Radial Lift for the suitable skid steer geometry is necessary.

Nonetheless, with job site demands requiring increased reach and deeper diggings, the introduction of the Telescopic Boom has upset the compact loader market. For such a business, knowing what structurally sets these two so different skid steers apart would be highly advantageous in optimising both your Return on Investment (ROI) and operational flexibility.

The argument of Telescopic Boom vs. Radial Lift is more than just a measure of a bucket height; it includes aspects such as the load trajectory, the chassis stability, and the machine’s capacity to collaborate in the solving of a reputedly impossible task single-handedly. Radial lift machines benefit greatly from their unchanged simplicity and excellent ground-engagement.

On the other hand, telescopic boom-mounted loaders allow the operator to make use of three-dimensional space for materials handling by extending not only vertically but also laterally. The operator can thus combine the advantages of a skid steer and those of a telehandler at the same time and, notably, can utilize a single side of a truck for loading or reach over the obstacles during the operation.

Why rely on the Radial Lift?

To put it simply, a radial lift is the original and therefore also the most tested and reliable skid steering geometry. The radial lift design is that which the radial arms are pivoted at only one point behind the foremost axle, and due to this, the entire length of the loader arms move in a curved, circular path.

The greatest benefit of this design lies where it is most often used; if the majority of the work performed is at ground level or just slightly above, the machine will be operating at maximum efficiency. In fact, because the radial lift skid steers have fewer parts and pivot points, they can generally generate higher breakout forces and so they are the best choice if one needs to dig very aggressively or do grading.

Radial lift is still on a par with the competition when the fleet is dominantly engaged in site preparation, landscaping or light excavation. The curve of the arc allows very precise positioning of the bucket when close to the ground for prying and pushing. The arms however become a limiting factor as they elevate; the load at the midpoint of the lift moves away from the machine and then at full height, it retracts back toward the cab, so it is not always effective for dumping into high-sided dump trucks.

- Greater Breakout Force: The mechanical advantage for prying and digging into tough soil is maximised by the single-pivot designing.

- Lower Maintenance Expenses: A smaller number of hinge pins and bushings lead to a decreased requirement for lubrication and a lower number of potential points of mechanical failure.

- Improved Visibility: Without the complicated linkage systems found in vertical or telescopic models, operators frequently benefit from an unobstructed view of the tires and work area.

Telescopic Boom: Enhancing Reach and Versatility

Thanks to the telescopic boom, the future of skid steer technology is now at your fingertips. Conventionally, radial and vertical lift modalities came with a fixed arm length, however, a telescopic boom changes this by allowing dynamic extension and retraction of the arm.

Thus, what was once impossible for a loader is now within its “reach”. Think about how great it would be to elevate a pallet over a fence without having to open the gate or, just think about how you can unload a flatbed trailer from one side only, because your boom reaches across the entire deck width.

This configuration is a blessing, especially when you have to deal with complex job sites where space is limited. Notably, a telescopic skid steer can reach heights greater than even the largest vertical lift loaders (typically exceeding a hinge pin height of 13 feet).

Additionally, it is the only design that allows a compact loader to dig below grade, achieving excavation depths of more than 3 feet. Thus, it serves as a perfect example of a “Swiss Army Knife” for the contractors who can do trenching, high-reach loading, and precision material placement with this single unit.

- Lift Height Unparalleled: Compared to standard radial loaders, telescopic booms can lift materials much higher, which is a feature that particularly benefits stacking of goods in warehouses where space is at a premium.

- More Than Surface-Level Reaching: Extending the boom downward can help to open up new application areas such as clearing water channels or digging the foundation without the use of an excavator.

- Side-Entry Access: Most telescopic models are single-arm designs which facilitate side entry doors, thereby enhancing operator safety and comfort of getting into the machine.

Comparative Analysis: Telescopic Boom vs. Radial Lift – Geometry and Performance Specs

In order to make a more fitting decision, one should come to terms with how these machines compare to each other technically on a side-by-side basis. In essence, the radial lift is a specialist in earthmoving, the telescopic boom, however, is a generalist that happens to have a specialist’s reach.

| Feature | Radial Lift Skid Steer | Telescopic Boom Skid Steer |

| Lift Path | Curved Arc | Dynamic (Up, Out, and Down) |

| Best For | Digging, Grading, Pushing | High-Loading, Reach, Stacking |

| Reach at Max Height | Limited (moves back toward cab) | Exceptional (extends outward) |

| Maintenance | Low (Single Pivot) | Moderate (Hydraulic Extension) |

| Digging Depth | Surface Level | Below Grade (up to 3+ feet) |

| Cost | Generally More Affordable | Higher Initial Investment |

Telescopic Boom vs. Radial Lift

Selecting Based on Application: Construction vs. Agriculture

Traditionally, the deciding factor between Telescopic Boom vs. Radial Lift in construction projects is usually which phase they are at. During the time of initial land clearing and bulk earth moving, it would probably be pretty hard to beat a radial lift for all-around durability and sheer pushing force. It is a workhorse for grading and backfilling.

However, when the structure is up and ready for the next stage, the telescopic boom is the perfect companion, be it for the pallets of bricks lifted to the second floor’s scaffolding or the loading of high-profile waste containers with debris that standard loaders simply couldn’t reach.

When it comes to agriculture, it is the telescopic boom that gets the green light more times than not due to its ability to “reach over”. For example, with the use of telescopic booms, farm tractors can easily circumvent feed bunks and also stack hay bales in a barn at a significant height.

Since the boom can be extended, a farmer is able to leave the field dry while the muddy or unstable areas are being loaded with heavy machinery. On the contrary, cleaning out the stalls and scraping concrete lots are tasks where the radial lift would generally be a better option due to its simple and low profile design in addition to being cost-friendly.

- Precision load placement: Telescopic booms aid greatly with pinpoint accuracy when placing materials on elevated platforms.

- Obstacle Navigation: Extension allows the machine to work over silt fences, curbs, and other site barriers without damaging them.

- Cycle Efficiency: Loading from one side of a truck saves the time usually spent driving around to the other side, increasing daily productivity.

Maintenance and Long-Term Ownership Costs

Another factor thorough consideration should be given to when deciding a right skid steer geometry for your fleet is the Total Cost of Ownership (TCO). Radial lift loaders are less expensive maintenance-wise, due to the manufacturer keeping the design as simple as possible. There are no extension cylinders to seal and no complex telescoping wear pads to monitor. For a rental fleet or a business where the machine is subject to high-abuse environments, the ruggedness of the radial lift is a significant asset.

On the other hand, the telescopic boom has a different way of cutting down costs that is inherently tied to equipment consolidation. A telescopic skid steer can substitute a traditional skid steer; a small telehandler, and with some light digging, even an excavator, so it would reduce your dependency on multiple machines going to the site. The maintenance required on the boom itself is undoubtedly more intensive, but this is just a fraction of higher fuel, insurance, and transport costs for the multiple machines that you are saving with one single unit.

- Grease points: The number of grease points in the radial lifts is less and so, the number of grease points will influence and determine how long the daily pre-start maintenance time can be.

- Wear components: Regular checking of wear pads is necessary for the telescopic booms to make sure that the boom slides well and stays aligned.

- Hydraulics: Telescopic models depend largely on high- tech hydraulic systems to control boom extension, which in turn necessitates the use of top-notch fluids and filter replacements.

Final Verdict: Which One Should You Choose – Telescopic Boom vs. Radial Lift?

Is your business all about ground-level earthmoving? If yes, then going for a radial lift is your smartest move overall. You will not find an alternative out there that can beat it when it comes to mechanical efficiency and cost. The radial geometry is optimized for lateral forces which in turn, equates to huge volumes of soil and gravel.

If however, your job site requires “verticality” in whatever form that may be—loading higher trucks, reaching over walls, or working in a confined space where you can’t really drive right up to the target—the telescopic boom would be the obvious choice between Telescopic Boom vs. Radial Lift. It elevates a skid steer from a bucket-pusher into a precision lifting tool. With the addition of telescopic geometry to your loaders, you are not merely acquiring another machine but you are gaining an opportunity to accept more complex and therefore better-paying jobs.

Telescopic Boom vs. Radial Lift – FAQ’s

Is a radial lift or vertical lift better for digging?

Radial lift skid steers are generally better for digging. Their single pivot design, results in higher breakout forces and the geometry of the arc is naturally optimized for prying and pushing at ground level.

What is the main advantage of a telescopic skid steer?

The main strength is unrivalled reach, going higher than traditional loaders, for over-the-fence type reaching and being the only compact loader that can dig substantially below grade.

Which skid steer lift type is best for loading dump trucks?

Vertical or telescopic booms are best for loading dump trucks. Radial lifts, which pull back the load towards the machine at full height, lack this feature and thus the load is dumped at the center of the truck bed by these machines.

Are telescopic skid steers more expensive to maintain?

Yes, their maintenance requirements are usually higher than those of radial lifts because of the additional hydraulic cylinders, extension sensors, and wear pads required for the telescoping action compared to the simple pivot of a radial lift.

Can a telescopic skid steer replace a telehandler?

In many light-to-medium applications, yes. Its capacity to lift pallets to high heights and reach across trailers makes it a viable, more maneuverable substitute on many jobsites despite it not having the massive capacity of a full-sized telehandler.

Does the lift geometry affect the stability of the machine?

For sure. When heavy loads are raised to the maximum height, vertical and telescopic models tend to be more stable as they keep the center of gravity closer to the machine’s wheelbase during the entire lifting cycle.

Why would I choose a radial lift over a vertical lift?

A radial lift will be the better option if most of your work involves grading, excavating or ground-level tasks and if you want a machine that is easier and cheaper to maintain, and also has a lower initial purchase price.