Fuel Efficiency for Skid Steer Loaders: Best Practices & Upgrades

Besides being an environmental goal, maximizing Fuel Efficiency for Skid Steer Loaders has become an essential step in ensuring the survival of a business in the highly competitive construction and landscaping industries today. Whether you are deploying a heavy-duty machine in an industrial site on a grand scale or a small-sized one in a residential project, the cost of diesel or gasoline will eat up your profits if you do not manage it properly.

Synergizing between mechanical health, operator habits, and technology upgrades is a key factor that owners must understand as their first step towards a more efficient and productive business.

Focusing on Fuel Efficiency for Skid Steer Loaders will allow owners to raise the profits potential of their equipment while lowering the operational costs significantly.

Importance of Fuel Efficiency for Skid Steer Loaders:

Knowing that every drop of fuel must be used for enough productive movement is the basic principle that defines saving fuel. Often, the root cause of inefficient operations is the failure in maintaining the machines regularly and, consequently, the old working patterns which make the engine load higher than necessary.

One of such examples is when a dirty air filter or one tire that is not inflated enough causes that the resistance which the engine has to overcome is increased (parasitic drag). In fact, if you work in a skid-steer loader company such as those at skidsteerloader.net, it will be very easy for you to keep your machines at their very best from day to day by carrying out the maintenance regularly in line with the performance control system you have established.

- Measure fuel consumption first so that you will know the machine or truck that gives a different value/figure.

- Make the hydraulic function changes gradually to avoid high power consumption for lifting.

- Use the good-quality fuel and lubricants to have high efficiency combustion and less wear inside.

Fuel Efficiency for Skid Steer Loaders Maintenance Practices:

1. Strategic Maintenance: The Core of Engine Economy

A non-negotiable practice for any Fuel Efficiency for Skid Steer Loaders performance enhancers is the absolute dedication to routine maintenance. To keep functioning well, engines that are kept running on rough parts naturally require more energy.

The air-to-fuel ratio is an extremely delicate balance; a producti ve machine requires lots of air to keep burning fuel efficiently. When an air filter gets clogged with soil at a work-in-progress site, the engine will resort to using extra fuel in order to keep the power constant.

The “rich” combustion that also results in wasted resources (i.e., fuel) is thus created. If the cooling system, including the radiator and oil cooler, is checked regularly, it will be ensured that the engine will run within its optimal range of temperature and, thus, prevent the inefficiency that comes from overheating.

It should also be noted, however, that the drivetrain and hydraulic systems can be a huge factor in fuel consumption. For instance, track tension adjustment is one of the main things to keep in mind while using a tracked machine such as the TYPHON STOMP.

If the tracks are too tight, they will create a lot of friction; if they are too loose, they will slip – both tensions are enemies of efficient fuel consumption by the machine. Fuel Efficiency for Skid Steer Loaders is also largely influenced by tire pressure. For example, just a 5% decrease in pressure can spike the rolling resistance up by 20%, which, in turn, causes the engine to use a lot more fuel to get across the site.

| Maintenance Item | Frequency | Impact on Fuel Efficiency |

| Air Filter Inspection | Daily | Up to 10% improvement in combustion |

| Tire Pressure/Track Tension | Weekly | Reduces rolling resistance by 15-20% |

| Hydraulic Fluid Levels | Daily | Prevents pump overexertion and heat buildup |

| Fuel Filter Replacement | Monthly | Ensures clean, efficient fuel delivery |

2. Operator Habits: Human Factors in Fuel Savings

The person operating the Fuel Efficiency for Skid Steer Loaders can be viewed as the primary factor in the overall effectiveness of machine performances despite the fact that such machines have now progressed so far technologically.

One of the main reasons for potentially huge wastage of fuel is the operator’s aggressive style of operation, which is, in essence, characterized by fast acceleration, fully opening the throttle and particularly hard and frequent braking.

Teaching operators how to carry out smooth, gradual courses of movements will not only make operations safer but will also enable the hydraulic system to naturally increase pressure without demand for an instant, high-energy burst. Newly developed models of loaders often come with a built-in feature that allows the RPM to remain in a “sweet spot” where torque and fuel economy intersect; staying within this spot for the completion of general tasks can translate into gallons saved from a week’s work.

Idling is another factor which silently reduces profits, though the evil of idling is widely ignored and even misunderstood by some. One of the misconceptions about the diesel engine is that it is better, on the whole, to leave it running than to turn it off and on again. However, engine manufacturers now develop their products in such a way as to enable the start and stop operations to be done with minimum wear.

Introducing a rule to stop idling over a five-minute period will be a huge step toward improving your Fuel Efficiency for Skid Steer Loaders. Here, the main idea is that the machine is powered down during any time period of change over and no power is being consumed by the engine unless it is very short.

This way of thinking not only helps to keep the fuel consumption low but also increases the machine’s reselling value due to the fact that only fewer working hours are accumulated and so long intervals between main overhauls are made possible.

- Provide training for “gear up and throttle back” light-duty tasks operators.

- Encourage “Eco-Mode” usage if the equipment features modern electronic controls.

- Promote “low and slow” material transport practice to minimize both wind resistance and spills.

3. Technological Upgrades and Attachment Optimization

Advances in heavy machinery technology have led to the development of several “smart” upgrades that can either be retrofitted or chosen in the case of new purchases to increase Fuel Efficiency for Skid Steer Loaders.

Telematics systems should be considered as the most revolutionary upgrade currently available since they receive real-time data on fuel burn rates, idle times, and engine loads, thus allowing fleet managers to identify the machines or operators who are underperforming. This method based on facts ensures that training and maintenance are properly targeted and that the entire fleet is kept in an optimum state according to the specific requirements on the job site.

The work done with the attachments makes a great difference in energy usage as well. When, for example, a big bucket is the one used or a high flow attachment on a standard flow machine, the system has no other option but to be pushed to its absolute limit. This means beyond any doubt that the fuel is going to be used up very quickly.

On the other hand, if, for instance, you were to use randomly a ripper or a land leveler form a skidsteerloader.net machine, you might realize that the total number of passes needed to complete the job has decreased. Some modern-day hydraulic systems even offer various upsides like high efficiency pumps and load-sensing valves, which in the end lead to power only being delivered when and where it is required, something that is indicative of the best Fuel Efficiency for Skid Steer Loaders.

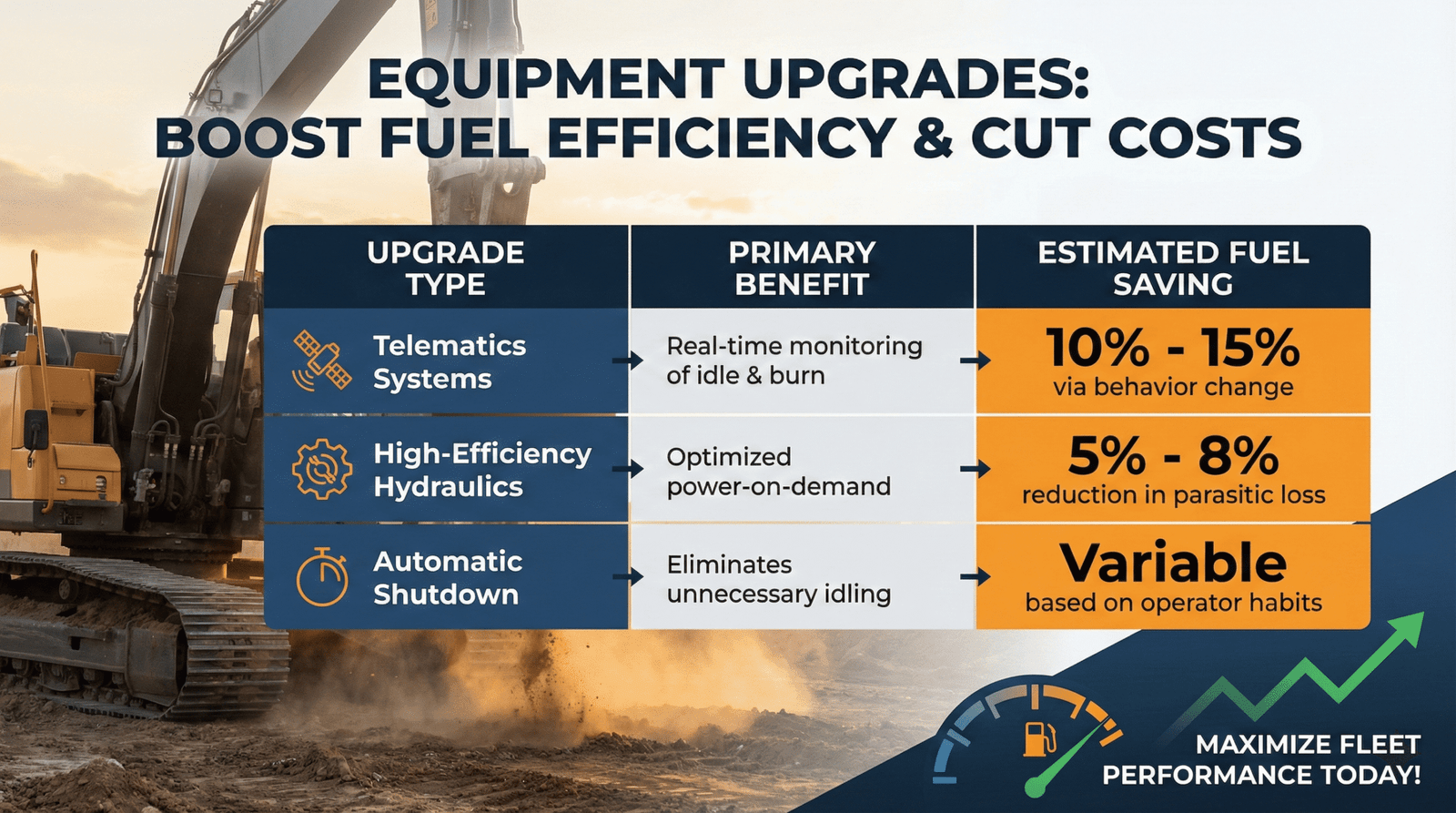

| Upgrade Type | Primary Benefit | Estimated Fuel Saving |

| Telematics Systems | Real-time monitoring of idle & burn | 10% – 15% via behavior change |

| High-Efficiency Hydraulics | Optimized power-on-demand | 5% – 8% reduction in parasitic loss |

| Automatic Shutdown | Eliminates unnecessary idling | Variable based on operator habits |

- Match the attachments with the machine’s Rated Operating Capacity (ROC) to avoid overloading.

- Opt for LED lighting to save energy and reduce the demand for a charging system on a vehicle.

- Take advantage of GPS-guided grading systems to limit the number of passes required for site preparation.

Fuel Efficiency for Skid Steer Loaders Comparison

4. Site Planning: Reducing the “Deadhead” Miles

One of the factors that impact Fuel Efficiency for Skid Steer Loaders which is hardly ever considered is the physical layout of a job site. Each time a loader moves without a load being carried it is like having a part of the journey known as “deadhead” which consumes fuel while it does not generate money.

Material stockpiles, fuel stations, and staging areas should be placed strategically to minimize the distance required for each travel cycle. Good site planning guarantees that the loader or loaders will spend most of their time doing the actual work (digging, lifting, grading) and will not have to walk much over the terrain.

Additionally, the conditions of the ground itself can influence the economy. For example, the power needed to negotiate soft, muddy ground is a lot more compared to compacted soil or gravel. In theory, if you can do it, cleaning up the site a bit can bring you some extra fuel drops.

For instance, you can keep your main haul roads well maintained so that they provide good surfaces for Fuel Efficiency for Skid Steer Loaders as these tracks or tires will have better grip and won’t slip as much. This will also facilitate the coordination with other equipments like dump trucks, which you’ll need if you want them positioned efficiently to give a short swing angle for loading. Thus, a streamlined and fuel-conscious workflow is created with these acts that are taken into consideration.

- Choose a centralized material hub so that the skid steer’s travel radius can be reduced to a minimum.

- Wherever it is possible, avoid steep grades on haul paths to prevent the engine from lugging.

- Task sequencing so that the machine can be used for several jobs that are located near each other before having to move across the site.

FAQs: Top Search Insights on Skid Steer Fuel Economy

How much fuel does a skid steer use per hour?

On average, a mid-sized skid steer consumes between 1.5 to 3.0 gallons of fuel per hour, depending on the engine’s horsepower and the intensity of the work. Heavy hydraulic tasks like mulching will be on the higher end, while light grading uses less.

Does idling hurt a skid steer engine or just waste fuel?

Both. Excessive idling causes incomplete combustion, leading to “wet stacking” or carbon buildup on the valves and injectors. While it certainly wastes fuel, it also increases maintenance costs over time.

What is the most fuel-efficient skid steer engine type?

Modern Tier 4 Final diesel engines and newer gasoline engines with electronic fuel injection (EFI) are the most efficient. Additionally, the industry is seeing a rise in electric and hybrid models for maximum efficiency in specific applications.

Can low tire pressure really affect my fuel bill?

Yes, it really can. The tires that are not inflated enough have more contact with the ground at their inconsistent surface areas, which causes more friction. As a consequence, the engine will have to work harder to keep up the speed, thus resulting in the efficiency being lowered by as much as 20%.

How do I know if my attachments are killing my fuel economy?

If your machine frequently “bogs down” or the cooling fan runs constantly while using an attachment, it is likely overtaxing the system. Matching the attachment to the machine’s hydraulic flow rate is key to Fuel Efficiency for Skid Steer Loaders.

Are tracks more fuel-efficient than wheels?

It depends on the surface. On hard, flat ground, wheels are more efficient due to lower rolling resistance. However, in soft mud or sand, tracks are more efficient because they prevent fuel-wasting slippage.

Does using “Eco-Mode” actually save money?

Yes, Eco-Mode typically caps the maximum RPM and optimizes hydraulic response for lighter tasks. For many general site duties, this can save 5% to 10% in fuel without a noticeable loss in productivity.