Pilot Controls vs. Hand/Foot: Which Skid Steer Control Type Boosts Operator Productivity the Most?

In the fiercely competitive arena of earthmoving and site preparation, the debate over Pilot Controls vs. Hand/Foot systems is not just a matter of preference—it is a significant decision that has a direct impact on your profits. Picking the right interface for your skid steer loader could be the determining factor between an operator who is worn out by midday and another who still operates with peak accuracy after ten hours.

With the advancement of technology, the devices we use become easier to operate. However, “modern” doesn’t always imply “better” in every case. In order to get the most out of your machine, you need to be able to measure the effects of the control systems on real-life productivity, maintenance expenses, and worker turnover.

Fundamental Differences: Defining Each Control Type?

Prior to comparing the productivity aspects, it is vital to determine what exactly we refer to by these two dissimilar styles of layouts. The hand and foot controls are the “old guard”—a mechanical heritage that the industry grounds on. Meanwhile, pilot controls (also known as ISO or H-pattern joysticks) are the newest standard features reflecting the hydraulic and electronic characteristics of the modern cabs.

- Hand/Foot Controls: This setup is using two pedals on the floor that control the arms and tilt of the bucket, and at the same time, the two hand levers work for moving and turning. It is a style that demands “total physical” involvement of the operator.

- Pilot Controls: Hydraulically assisted joysticks or electronically over hydraulics. Commonly, the left hand joystick works for keep the machine moving while the right one operates the boom and bucket.

- The Hybrid Approach: A few newer models have “Selectable Joystick Controls” (SJC), so the operator can choose the pattern, however, it is still a joystick that is used as the physical tool, rather than a pedal on the floor.

The Productivity Powerhouse: Why Pilot Controls Are Winning the Modern Jobsite

Unlike the first impression that productivity is only about speed, it is equally about consistency of the operator’s performance. When we debate Pilot Controls vs. Hand/Foot, we most probably bring up the issue of operator fallen energy. A machine equipped with pilot controls is very easy to maneuver and thus the operator can spend less time and energy on correcting the errors and the final outcome is more accurate.

Reduced Physical Strain: Not having to constantly press

Intuitive “Video Game” Logic: The young generation of operators, brought up in the world of digital devices, are quickly adapting to pilot controls. This leads to a decrease in the “learning curve” when hiring new personnel.

Fine-Tuning & Precision: In rare cases, pilot controls have to face the lack of pressure to achieve the “feathering” (the choice of very accurate and almost imperceptible changes in the height of the bucket or the speed of the machine, something that is very hard to be done by using the inefficient mechanical elements).

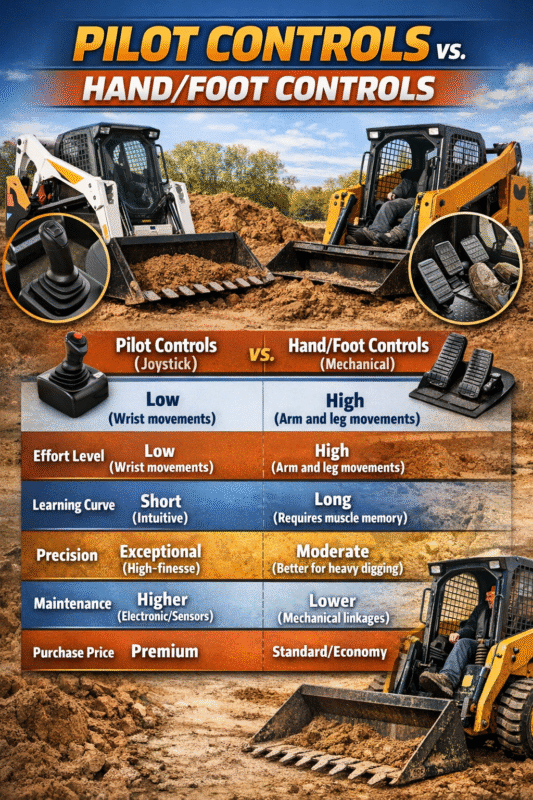

Table: Pilot Controls vs. Hand/Foot

| Feature | Pilot Controls (Joystick) | Hand/Foot Controls (Mechanical) |

| Effort Level | Low (Wrist movements) | High (Arm and leg movements) |

| Learning Curve | Short (Intuitive) | Long (Requires muscle memory) |

| Precision | Exceptional (High-finesse) | Moderate (Better for heavy digging) |

| Maintenance | Higher (Electronic/Sensors) | Lower (Mechanical linkages) |

| Purchase Price | Premium | Standard/Economy |

| Feature | Pilot Controls (Joystick) | Hand/Foot Controls (Mechanical) |

| Effort Level | Low (Wrist movements) | High (Arm and leg movements) |

| Learning Curve | Short (Intuitive) | Long (Requires muscle memory) |

| Precision | Exceptional (High-finesse) | Moderate (Better for heavy digging) |

| Maintenance | Higher (Electronic/Sensors) | Lower (Mechanical linkages) |

| Purchase Price | Premium | Standard/Economy |

Preserving the Good Old Days: The Use of Hand and Foot Controls Still Has Its Advantages

Indeed, the landscape is heading towards joysticks, but hand and foot controls are still very useful. For many veteran operators, the physical feedback coming from the handle of the lever is something that they cannot do without. They actually have a “tactile” sensation of working with the machine, in such a way that the change of the signals to electronics cannot be able to imitate it.

- Ari Unmatched Tactile Feedback: The hydraulic components are always in direct contact with the mechanical bodies thanks to the latter. If the bucket bumps into the underground stone, the operator will immediately feel the vibration through the levers.

- Simplified Maintenance: Since there are less sensors and electronic modules, hand/foot machines are often easier to repair in the field with basic tools.

- Investing Less Initially: The traditional style of control-equipped machines usually come with a lower price tag, which makes them an attractive option for the rental fleets and the contractor startups.

Pilot Controls vs. Hand/Foot Comparison

Ergonomics and Long-Term Operator Health

The controversy between Pilot Controls vs. Hand/Foot is not a matter of speed but one of health. Carpal tunnel syndrome, back pain, and knee problems are all work-related, heavy-equipment operating injuries. Furthermore, a better ergonomic operator cab is no longer just a “nice to have”; it is one of the main strategies in your toolbox of employee retention.

- Seat-Mounted Stability: One of the main advantages of pilot joysticks is that they often get mounted on the seat itself and not on the rest of the cabin. In this way, the “joystick bounce” issue that results from the jerks caused by the unevenness of the ground is prevented because the controls move with the operator.

- Adjustable Armrests: With the use of pilot controls, one can comfortably rest the forearms and navigate by using just tiny movements of the wrist. This has the effect of reducing the odds of Repetitive Strain Injury (RSI) considerably.)

- Customizable Sensitivity: A good number of pilot-controlled loaders let you manipulate the so-called “response rate.” You can “program” the machine for “aggressive” loading of trucks or “soft” when doing careful grading around the foundations.

Productivity Metrics: A Comparison of Cycle Times

There is no doubt that in operations where it is necessary to handle large volumes of material, such as loading a dump truck or backfilling a ditch, every fraction of a second is going to count. From the perspective of the industry, although hand/foot controls give you powerful “breakout force” for heavy digging, pilot controls are the ones that contribute most to “cycle efficiency.”

- Loading Trucks: By using joysticks, an operator can do “lift and tilt” simultaneously and still move forward during the operation, this is a lot easier than having to coordinate the use of both feet and hands.

- Grading & Leveling: Piloting a machine with a simple system allows you to do the job in fewer rounds while the touch-up time is also less.

- Attachment Versatility: Advanced attachments such as 4-in-1 buckets or cold planers require auxiliary hydraulic buttons to be placed right on the joystick head, which greatly facilitates their operation in contrast with coming to the separate floor lever.

Making the Choice: Which Control Type is Right for Your Fleet?

Eventually, deciding between Pilot Controls and Hand/Foot really hinges on the nature of your business model. If you are simply a solo-owner operator, who has been using foot pedals for 30 years, switching to joysticks might actually lower your productivity in the short term. However, for a company that is expanding and actively seeking talent from the next generation, pilot controls are undoubtedly the most rational choice.

- Think about Your Fleet Mix: In case your other equipment (say mini excavators) are operated with joysticks, it would thus be reasonable to keep the controls on your skid steer the same so that your operators can easily move from one machine to another.

- Job Type: Hand/foot controls are great for rough grading and heavy excavation work where durability matters. On the other hand, pilot controls have the edge when it comes to landscaping, snow removal, and urban construction where finesse is paramount.

- Budgeting for the Future: Paying a bigger upfront cost for pilot control often turns out to be a great investment as less fatigued staff and more precise work will usually be able to pay off the upgrade within the first 1,000 hours of operation.

FAQs – Pilot Controls vs. Hand/Foot

Are pilot controls harder to fix than hand and foot controls?

Basically, yes. Pilot controls mostly rely on electronic sensors and solenoids, which can only be diagnosed with the help of the appropriate software. On the contrary, hand and foot controls are levers and linkages which can be easily adjusted with a wrench or other mechanic’s tools.

Can a skid steer be changed from foot controls to joystick controls?

No, this is not a simple “plug and play” upgrade. Internal hydraulic valves and wiring harness differ to such an extent that you have to change everything if you want to switch from one type to another. Therefore, the choice of the preferred controls should be done before the purchase.

Why do some operators still prefer hand and foot controls?

It is all about experience and “feel”. A great number of seasoned operators have been doing the same for such a long time that their muscle memory is almost perfect. They “feel” the load through the mechanical levers, which gives them an extra sense of control that the electronic joysticks sometimes lack.

Which control type is better for beginners?

As far as beginners are concerned, pilot controls (joysticks) are much less intimidating. “Left-hand drive, right-hand boom” is a very intuitive method that is not only the same as excavators’ controls but also is very similar to those of video games.

Do pilot controls increase the resale value of a skid steer?

Surely. Since the whole industry gradually heads towards better worker health standards, the used machines with pilot controls or with Selectable Joystick Controls (SJC) tend to be higher in demand and thus, have better resale value than those of traditional hand/foot models.

What is “ISO” vs “H-Pattern” in pilot controls?

The ISO pattern presumes the left hand is for the driving and the right for the bucket; in the H-Pattern, both hands are used for driving (the left stick controls the left wheels, the right stick controls the right wheels) and the sideways movement is for the bucket. Many pilot systems allow you to switch between these two with a button.

Does the control type affect the machine’s lifting capacity?

Not at all. The lifting capacity (Rated Operating Capacity) is basically the amount of weight the machine can raise, which is decided by the hydraulic pump, the size of the frame, and the counterweight of the machine. The control type is the only thing that changes the way the operator operates those systems.