Skid Steer Trenchers: The Essential Skid Steer Attachment for Utilities, Irrigation, and Drainage

In today’s rapidly changing construction and landscaping industries, gaining more efficiency and thus increasing profits is what really matters. A Skid Steer Trencher is now widely regarded as a very powerful piece of equipment that converts an ordinary skid steer attachment to a very potent digging machine.

It does not really matter whether you are running a utility project laying fiber optic cables across a city or you are a commercial vineyard that needs a sophisticated irrigation setup; the skid steer trencher delivers accuracy and speed that hand excavation cannot dream of.

By using the hydraulic power of your forklift, this tool literally cuts through the toughest ground including stony soil and even frozen soil thus helping you to keep your project in time and within budget.

Purchasing a first-class Skid Steer Trencher

Purchasing a first-class Skid Steer Trencher is more than just digging holes. The main thing here is to ensure the correctness of the structure of the installation that you do. You see, the regular buckets are capable of creating very large and untidy holes that will have to be filled and the whole site restored.

But if you use a skid steer trencher instead, it produces a clean, slim vertical cut that results in less disturbed soil. This is extremely important for the utility workers who have to cope with very tight easements and those who do landscaping and want to keep the look of the site after finishing.

Looking at the changing requirements in the field of modern infrastructure, the ability of the Skid Steer Trencher to change from one task to another is still unsurpassed.

The Role of Skid Steer Trenchers in Utility Installation

Every utility contractor has to contend with the problem of, on the one hand, conforming to the exact level requirements and, on the other hand, having to protect his work against damage caused by the unknown presence of an underground line.

The Skid Steer Trencher is designed with these problems in mind and the solution provided is very precise operation. It should be noted that almost all of the latest models of this equipment come with a feature of a depth control which can be adjusted allowing the operator to always set the boom to the desired depth–generally this can be anywhere from 24 to 60 inches–thus ensuring that gas, water, and electrical lines are safely buried below the frost line.

- Long Subsistence Capacities: High-flow models can reach depths of up to 5 feet, which is essential for the installation of municipal water mains and deep-buried electrical conduits.

- Chain Customization: Operators can select from “cup teeth” for soft soil and “shark teeth” or “rock & frost chains” for cutting through asphalt or frozen ground.

- Spoil Management: Built-in augers carry the excavated soil to one side, thus keeping the trench edge clean and making the backfilling process much faster.

Streamlining Irrigation Projects with Precision Trenching

Water is the main factor of production in the landscape and agriculture sectors. Hence, the Skid Steer Trencher is the favorite piece of machinery when it comes to installing irrigation systems’ lateral and main lines. The advantage of these machines is their size and ability to maneuver easily so that they can work around trees, garden beds, or pass through narrow gates where a ride-on trencher would be too bulky to use.

- Uniform Width: Trenchers have a consistent trench width (generally 6 to 12 inches), which stabilizes the position of pipes and thus lowers the demand for costly bedding material.

- High-Speed Operation: Relative to an excavator, a Skid Steer Trencher is capable of covering more linear feet per hour, which significantly lowers the labor cost of large-scale irrigation installations.

- Minimal Surface Damage: A skid steer equipped with turf-friendly tracks or tires will leave hardly any marks on the lawn, thus post-installation cleanup will be minimal.

Elevating Drainage Options for a Sustainable Future

If the drainage is done well, the laying of the foundation becomes very stable and one can avoid expensive problems of erosion. Skid steer trencher is a reliable tool for creating different types of drainage like French, curtain, and bioswale drains.

By precisely cutting a channel, it helps in the right placement of perforated pipes and gravel, which in turn, leads to water being effectively diverted from the critical parts of the building.

- Precise Grading: Skilled users employ the skid steer’s tilt and lift features to keep a tiny slope at the bottom of the trench, which is just enough for gravity-fed drainage to work.

- Crumber Bar Integration: Most high-end trenchers come with what is known as a “crumber” or “scuff bar” that follows the trench chain and scrapes the bottom, thereby removing loose soil and providing a perfect finish.

- Attachment Versatility: A Skid Steer Trencher can be used by a contractor not just to dig the line but also to carry out the gravel or drainage tile placement after switching to the pallet fork or bucket. All this can be done with just one machine.

Key Technical Specifications of Skid Steer Trenchers

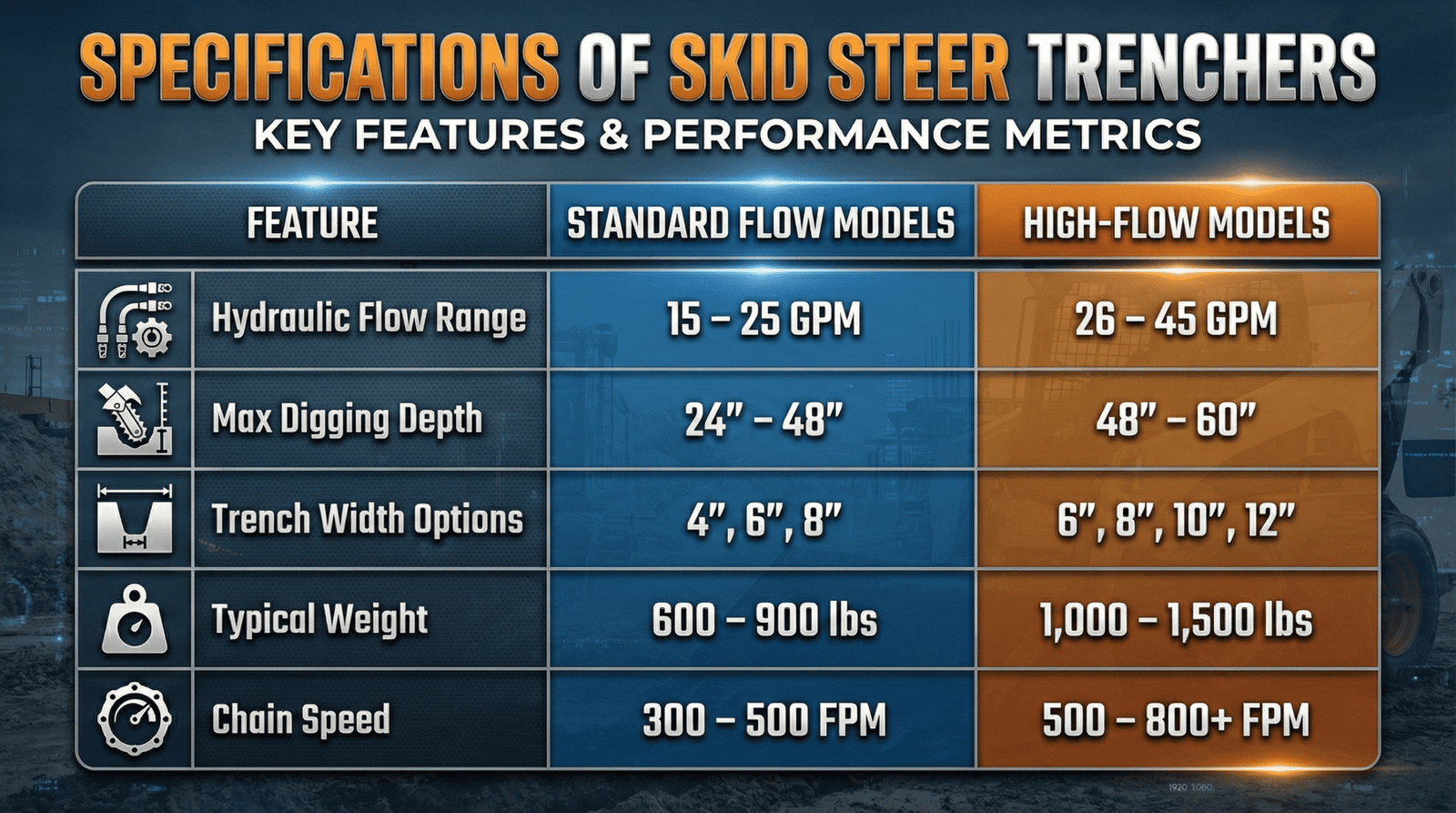

| Feature | Standard Flow Models | High-Flow Models |

| Hydraulic Flow Range | 15 – 25 GPM | 26 – 45 GPM |

| Max Digging Depth | 24″ – 48″ | 48″ – 60″ |

| Trench Width Options | 4″, 6″, 8″ | 6″, 8″, 10″, 12″ |

| Typical Weight | 600 – 900 lbs | 1,000 – 1,500 lbs |

| Chain Speed | 300 – 500 FPM | 500 – 800+ FPM |

Skid Steer Trenchers and Skid Steer Attachment Features

Maintenance Tips for Your Skid Steer Trencher

If you want to keep your Skid Steer Trencher working smoothly for a long time, the thing you cannot compromise on is scheduling the routine check-ups ahead of time. Due to the nature of the work that involves digging, friction is very high and thus teeth, chains, and sprockets can be considered consumable parts that require regular checks. Besides the fact that a well-kept attachment lasts longer, it also exerts less pressure on the skid steer’s hydraulic system.

- Inspect Chain Tension: A loose chain can cause the sprocket to be jumped and the boom to be damaged, however, an overly tight chain will wear out the bearings very quickly. Normally, you should be able to insert two fingers between the chain and the boom.

- Regular Lubrication: Every 8 to 10 hours of operation, coat the grease at the pivot points and the nose roller bearing in order to prevent heat buildup and seizing of parts.

- Examine Teeth Sharpness: When teeth are blunt the hydraulic motor is forced to work harder which leads to higher fuel consumption and slower digging. To keep performance at a high level, replace broken or rounded teeth without delay.

FAQ’s on Skid Steer Trenchers

How deep can a skid steer trencher dig?

The majority of standard Skid Steer Trencher accessories are capable of digging between 3 and 4 feet deep. Increasingly, heavy-duty high-flow equipment can theoretically reach 5 feet depth (60 inches), which makes them perfectly suitable for municipal and residential utility projects.

Can a skid steer trencher cut through tree roots?

The answer is yes. If equipped with a combination chain or “shark teeth,” a Skid Steer Trencher can very efficiently handle small and medium-sized tree roots. Stalling the hydraulic motor can be avoided if operators go very slow with very large roots.

What is the difference between a dirt chain and a rock chain?

A dirt chain is fitted with “cup teeth” meant to scoop loose soil. Meanwhile, a rock chain is normally (frost chain) equipped with carbide-tipped teeth which are very effective in breaking hard clay, frozen earth, or rocky terrain.

Does my skid steer need “High Flow” hydraulics for a trencher?

Many Skid Steer Trencher units remain operable under a standard flow (15-25 GPM), and in fact, “High Flow” is advantageous for operations in harsh environment and at depths above 48 inches. Besides, high flow supplies the extra torque which is necessary for chain speed to be maintained under heavy load.

How fast can a skid steer trencher dig?

Your average scooping rate depends greatly on the type of soil and depth. For instance, in an ideal loamy soil at a 2-foot depth, a Skid Steer Trencher may achieve 5 to 10 feet of trenching per minute. On the other hand, in rock or hard clay, the speed drops substantially for a clean cut to be attained.

Can I use a trencher on a mini skid steer?

You bet! There exists a range of mini Skid Steer Trencher attachments meant for use on smaller platforms. When space is tight and full-sized loaders cannot fit, these little helpers come to the rescue for irrigation and backyard drainage works.

Is a skid steer trencher better than a mini excavator for trenching?

When it comes to lengths that are straight and uninterrupted, a Skid Steer Trencher is able to create a very neat and narrow trench at a much faster rate. But if the digging has to be done around the obstacles or one wants a very wide trench, then a mini excavator is the right choice for versatility among skid steer attachment.

Conclusion: Why Every Contractor Needs a Skid Steer Trencher

The multiplicity of functions that a skid steer loader can perform depends only on the variety of its skid steer attachment. By incorporating a Skid Steer Trencher in your machinery pool, you grant yourself the power to handle utility and drainage contracts that are very profitable and were until now beyond your reach.

It is a device that returns the money invested in it by the saving of labor, by its accuracy, and by its ability to do the work in the spot where other machines have to give up. Browse SkidSteerLoader.net to get acquainted with trenching technology that is state-of-the-art and to find the best match to your machine.