Skid Steers in Roadwork: Essential Machines & Attachments for High-Efficiency Pavement Projects

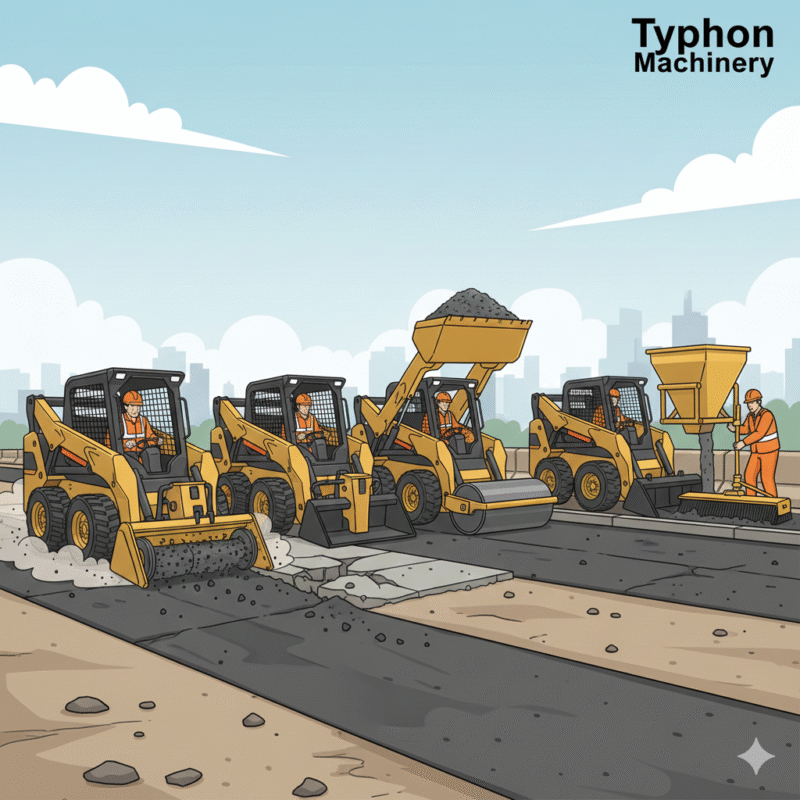

When was the last time you drove by a road construction site? What I want to know is, whether you saw the power machine that was moving fast and did almost everything from scraping old asphalt to compacting new gravel? Most probably, it was a skid steers in roadwork.

Hardly ever recognized alongside the gigantic excavators and dump trucks, the little skid steer is the main hero of the contemporary roadworks, particularly in the case of highly-efficient small-to-mid-sized pavement projects. Due to its compact size, agility, and unbelievable versatility – thanks to the huge range of available attachments – it is an essential machine capable of doing everything from surface preparation to the final smooth finish.

Why the Skid steers in roadwork is the best MVP?

Single-function specialists used to be the norm for road maintenance and small-scale paving. However, nowadays, the industry has been turned upside down by the fact that a skid steer can perform different kinds of work just by changing an attachment.

Compact workhorses like these are knotted to be pivotal in the industry for such reasons:

Unmatched Maneuverability: Skid steers in roadwork are equipped with a zero-turn radius, thus, they can turn around their axis. This feature is very important for maneuvering in close quarters, getting around utility poles and manholes, and operating in congested city streets where space is scarce.

- Cost-Effectiveness: What is the point of renting three different machines if one machine can do the work of three? The equipment rental, transportation, and labor costs can be significantly reduced by only one skid steer with a set of attachments.

- Versatility Through Attachments: The most prominent feature of a skid steer is its hydraulic quick-attach system. With this, the operators can change the implements quickly and easily, thus, they can move from milling to sweeping and to compacting in no time.

Skid Steers in Roadwork

The Essential Attachments for High-Efficiency Pavement

Either for asphalt or concrete pavement projects, the most important thing is the right attachment. These are the devices that will convert your usual skid steer into a specialized road construction machine.

- The Pavement Prepper: Cold Planer (Milling Attachment)

Typically, the removal of the old and worn-out road precedes the laying of a new one. That’s the point where the cold planer (or asphalt mill) comes in.

- Function: The idea is that it has a rotating drum equipped with carbide-tipped teeth, which are used for the precise milling or grinding of asphalt or concrete to a specified depth.

- High-Efficiency Use: The device can be employed in the removal of cracked pavement, the leveling of uneven surfaces, and the cutting of trenches for utilities. By this, it becomes possible to have a neat and even surface which is very important for the duration of the fresh road.

- The Demolition Dynamo: Hydraulic Breaker

For instance, if you want to break down a huge piece of concrete or a section of the pavement that is too old and too heavily damaged, the best and the most powerful tool to go for is the hydraulic breaker.

- Function: This is a very powerful, heavy-duty, mechanized hammer, which attaches to the skid steer’s hydraulics and, thus, can deliver fast, high-impact, and strong blows, thereby, effectively turning the solid material into easy-to-handle rubble for removal.

- High-Efficiency Use: It is a must-have tool for a fast and targeted demolition, e.g., detaching sidewalk, curb, or heavily distressed patches of the roadway.

- The Compaction Commander: Vibratory Roller

How good a road will be and for how long it will last, entirely depends on whether the compaction will be done properly or not. The vibratory roller tool helps to ensure that the materials are dense and stable.

- Function: The main part of this tool is a heavy steel drum that vibrates while it is rolling and thus it uses the immense dynamic force to compact soil, gravel, and newly laid asphalt patches.

- High-Efficiency Use: The main purpose of the attachment is to achieve the densification of the sub-base materials, asphalt patches, as well as small parking lots and can thus deliver a smooth, firm, and solid finish without the need for a large, dedicated roller.

- The Material Mover: Utility Bucket and Dispensing Bucket

Going back to the statement, “you can’t build a road without moving materials”, the bucket is the vehicle that does the transporting work.

- Utility Bucket: Most commonly the device is employed in the work of scooping, lifting, and transporting materials such as dirt, gravel, and large debris.

- Dispensing/Concrete Bucket: The buckets have been designed with the side or the bottom discharge chute for the purpose of accurate pouring of concrete, asphalt, or any other flowable material, thus, they help a lot in reducing wastes and messes on the job site.

- The Finishing Touch: Angle Brooms and Sweepers

Nothing less than the cleanup will do in the case of high-standard skid steers in roadwork.

- Function: These are the implements that make use of the hydraulics-powered rotorized-activated bristles for the purpose of cleaning dirt, rubbish, and millings.

- High-Efficiency Use: The main job of these machines is to get rid of the leftovers from the works area fast thus leaving it ready for the next step, be it asphalt application or traffic, or even a pristine final site.

FAQs on Skid Steers in Roadwork

Can a skid steer actually lay asphalt for a road?

They certainly can! Though they are not capable of making a four-lane highway, they are very efficient for smaller jobs. A Skid Steer Asphalt Paver attachment can spread and level hot asphalt with a high degree of accuracy, which makes it the right tool for driveways, patching, sidewalks, and small-scale road repairs.

What is the difference between a wheeled skid steer and a tracked one for pavement work?

The main difference between a wheeled and a tracked skid steer for pavement work is that the former is more suitable for work on hard surfaces which are already in place (like sweeping or milling) and the latter is better for ground preparation or work on soft/uneven soil. Thus, a wheeled skid steer is good in that it is faster, more maneuverable, and its tires are less expensive to replace, while a compact track loader (CTL) has the advantage of its tracks providing better flotation and traction.

Are skid steers powerful enough for heavy-duty concrete demolition?

Yes, indeed. As a hydraulic breaker or hammer attachment completes, a contemporary skid steer is capable of delivering a huge amount of force and thus can do the job of demolition of thick concrete slabs, heavy-duty foundations, as well as reinforced, on-the-hand, pavement pieces which are very hard to be dealt with by human labor.

How deep can a cold planer attachment cut into a road surface?

The cutting depth for different models is not the same, however, most of the high-flow cold planer attachments can mill 4 to 6 inches down (approximately 10 to 15 cm) in one pass. This is depth enough for full-depth patching and resurfacing in most cases.

How does a skid steer save time on a patching job?

The main factor for time shortening is a single machine’s versatility and speed of changing the attachments. With only one machine, a team can come to the spot, the breaker to taking out the old patch, the bucket to loading the debris, the cold planer to squaring the edges, and then the dispensing bucket to pouring the new material—all in a fraction of the time it would be if multiple specialized units were brought in.

Do I need a high-flow hydraulic for skid steers in roadwork?

If you want to work with the maximum of power and efficiency, the answer is yes, a high-flow hydraulic system is the one you should go for. In fact, the most performance and speed-demanding attachable like cold planers, wheel saws, and heavy-duty mulchers need a very fast hydraulic fluid flow(high GPM) to be able to work at their peak level and speed, which is extremely important for high-efficiency projects.

What is a “Wheel Saw” attachment used for Skid steers in roadwork?

A wheel saw (or rock saw) is an attachment that is used for the purpose of making very neat, deep, and narrow cuts in either asphalt or concrete. This is very necessary for installing the utilities such as electricity or water, for example, under a road, because it produces less material that has to be taken off and replaced compared to a wider trench.

Skid Steers in Roadwork: Essential Summary

Skid steer loaders aren’t simply one of the general construction equipment pieces; they’re a precisely engineered system of mobility and hydraulic power, specially designed to meet the fast-paced needs of modern roadwork and pavement maintenance. Contractors can greatly improve their efficiency, lower their costs, and be able to produce better quality results on all of their projects by maximizing the utility of one platform with specialized attachments.