Skid Steer Wheel Saws: Efficient Asphalt & Concrete Cutting for Utility Work

Skid steer wheel saws have changed the way the contractors and the utility professionals cut the asphalt and the concrete. These attachments are loved because they are accurate, can easily be carried to the different locations and can handle the tough cutting jobs without any problems.

Wheel saws, which are specially made for skid steer loaders, make it possible to facilitate the quick and clean cuts in different construction and utility works, thus, they have become an indispensable tool in the modern job sites.

The Need for Efficient Cutting Solutions in Utility Work

Working in the utility and infrastructure projects is a tough job and in such field accuracy when cutting the asphalt and concrete means less time to complete the projects, less wastage of the material and increased safety.

Skid steer wheel saws are the perfect choice in such situations due to their adaptability and power. They give the operators an opportunity to make the detailed cuts fast i.e. whether they are trenching for pipelines or making expansion joints without the need for larger and more heavy equipment.

Today, the modern wheel saws are getting smarter, more durable, and can handle even more complicated tasks due to technological advancements and thus, they become a must-have in every contractor’s work tool kit.

The Features and Benefits of Skid Steer Wheel Saws

Skid steer wheel saws have been designed with a number of features which make the works more productive and safer. They come with diamond-tipped blades, adjustable guide assemblies, and strong hydraulic systems suitable for hard or soft materials. These features create the following benefits:

- High Cutting Precision: As a result of accurate and clean cuts in asphalt or concrete, minimal material wastage and surface damages.

- Portability and Ease of Use: The device size is the main factor which guarantees the easy transport and movement in the tight or cramped spaces thereby it is perfect for utility maintenance and repair works.

- Versatility: This attachment turning off is not the only one you have; it is the most suitable for various areas such as trenching, demolition, and a lot of others, thus becoming a valuable multi-purpose tool.

Superior Cutting Capabilities for Asphalt and Concrete

Skid steer wheel saws are powered to cut through hard materials like asphalt and concrete without breaking a sweat. In fact, these attachments are capable of completing both small-scale utility repairs and big roadwork projects efficiently. To ensure long-lasting performance on abrasive surfaces, their diamond-coated blades provide durability.

Additionally, the saws come with provisions for depth adjustment, enabling the operators to have full control over the depth of the cut, which is very important in utility work when exactly how deep the trench has to be is often part of the requirements.

Skid Steer Wheel Saws Key Features – Enhance Cutting Efficiency

- Diamond-tipped Blades: These are the foremost cutting time blades and deliver the highest precision, top performance, and quality, least of all on hard materials.

- Adjustable Cut Depth: This feature enables the user to define the exact size of the utility trenches or surface cuts.

- Hydraulic Drive System: This is the reason why the machine is continuously running at maximum power and peak efficiency even in heavy load or harsh work scenarios.

Applications in Utility and Construction Sectors

Skid steer wheel saws are the most widely used devices in the power and energy industries and are foremost needed for precision and time-saving tasks. Performing the following works:

- Trenching and Utility Line Installation: The most environmentally friendly way of putting the pipes, cables, and conduits by the least surface disruption.

- Road and Pavement Cutting: The primary tasks for which the machine is employed are the production of temporary joints, the repair of the patched areas, and the placing of the new utilities underneath the roadways.

- Demolition and Surface Preparation: The right equipment for the work of tearing off the pieces of concrete or preparing the surfaces for the new pavement.

Skid Steer Wheel Saws Benefits in Various Job Sites

- Reduced Downtime: The major part of the time that is saved is actually the time that is used in fast switching between different cuts or jobs.

- Enhanced Safety: The risk of the surface cracking or causing an accidental damage is very low, as the cuts are done in a controlled manner.

- Cost-effectiveness: Traditional methods of saws or breaking-out require more labor and the use of more equipment, thus resulting in an increase in costs. Therefore, the current method is a cost-effective one.

Skid Steer Wheel Saws

Choosing the Right Skid Steer Wheel Saws

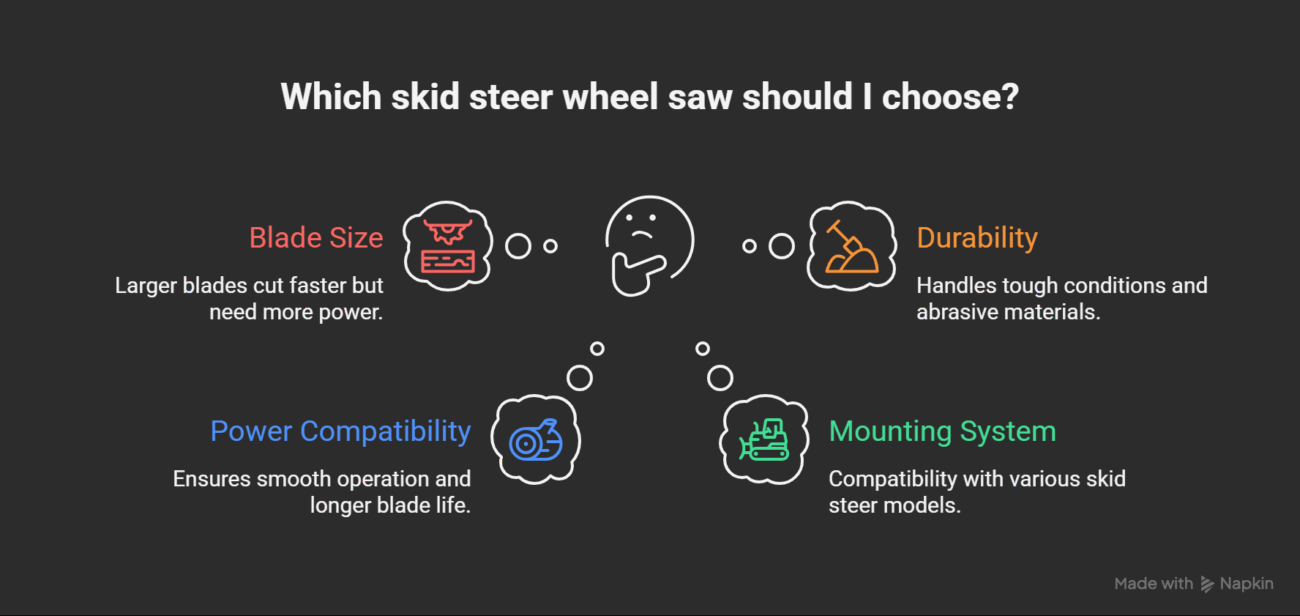

In the case of a skid steer wheel saw, to make a wise decision one should take into consideration the points mentioned below, and this will result in the performance at its best:

| Feature | Consideration | Why It Matters |

| Blade Size | 12”-24” diameter | Larger blades cut more material faster but require more power. |

| Power Compatibility | Hydraulic flow and pressure | Ensures smooth operation and longer blade life. |

| Mounting System | Universal or custom fit | Compatibility with various skid steer models. |

| Durability | Heavy-duty components | Handles abrasive materials and tough working conditions. |

Maintaining Your Skid Steer Wheel Saw for Longevity

Regular upkeep keeps your wheeled saw in good working condition for a longer time, thus it can keep delivering the desired results:

- Make it a habit to check the condition of the blade and change the worn out ones.

- Maintain cleanliness of the hydraulic connections and check for leakage.

- Do the lubrication of the moving parts and guide assemblies in order to prevent them from wearing.

Incase of not being used store your device appropriately in a dry and safe place.

FAQs About Skid Steer Wheel Saws

What size wheel saw is best for utility work?

Usually, blades from 12” to 18” are good for most utility works and they provide the balance between the size and the ease of handling.

Is it possible for skid steer wheel saws to go through reinforced concrete?

Definitely, with the use of diamond-tipped blades and high-powered hydraulics, these saws can penetrate reinforced concrete in a short time.

What safety measures should be followed when operating a wheel saw?

The operators should wear the necessary PPE, make sure the blade is properly installed and follow the manufacturer safety guidelines during operation.

How long are the blades?

The long-lasting of the blade depends on the hardness of the material and how often it is used, normally it is several hundreds of hours of use.

Are skid steer wheel saws good for small-scale works?

Definitely, the portability of them makes the perfect for detailed, smaller utility or repair work.

What is the average price of a skid steer wheel saw attachment?

The cost is determined by the size and the features while the price is generally between $3,000 and $8,000.

Can wheel saws be used for removal of asphalt?

Yes, they are highly effective for asphalt cutting, especially in utility trenches and pavement repairs.

Summary and Final Thoughts

Skid steer wheel saws are the tools which are changing the way asphalt and concrete cutting are done, basically within the utility sectors where precision, efficiency, and Safety are of great importance.

Their compact design together with the advanced diamond- tipped blades and hydraulic systems is what ensures the high-quality cut in the harsh working conditions. By choosing the right wheel saw attachment, you not only improve the work output but also save on labor costs and shorten the project duration. In the future, as technology keeps on evolving, these attachments will become more intelligent, tougher, and indispensable for utility, road construction and surface repair projects.

This detailed guide underscores the relevance of the quality skid steer wheel saw selection and the best working practices to unleash their full potential. Whether you are doing minor repairs or large-scale utility projects, the use of these attachments is the way to your success at the job site.