Urban Construction: Compact Skid Steer Loaders for City Jobsites

The infrastructures, economic renewal, and strict residential constraints make very often modern cities change rapidly. Urban construction projects require large-scale power and heavy-duty performance, however, the working area is most of the time measured in inches. Powerful and adaptable equipment are the ones which can handle tiny streets, protect sidewalks, and work quietly near homes.

The mini skid steer loader is the urban project ultimate workhorse. These little machines provide hydraulic power, skid steer mobility, and logistical ease which large, standard heavy equipment can hardly match in cramped urban areas. Transitioning to smaller and more versatile equipment changes municipal construction planning and execution which is more inclined towards minimal disruption and compact equipment efficiency from foundation to landscape detail.

Navigating the Urban Jungle: Why Size Matters for City Work

Space limitations are the main factors of urban construction projects that are reflected in staging and material supply and also in the operation. Large equipment is strong, but it requires complicated road closures, several permissions, and huge logistical support, thus increasing both costs and schedules.

On the other hand, compact skid steer loaders are built for these confined environments and therefore they offer contractors a great advantage in urban competitive marketplaces. Their streamlined design allows them to fit into normal business entrances and small back alleys, thus lessening their footprint and enabling them to access the previously unworkable areas of the projects. Being compact means speedier project completion and less neighborhood disruption thus meeting municipal impact criteria.

- Reduced Footprint: The small dimensions of a mini skid steer allow operation near utility lines, established trees, and existing structures without the risk of damage, a crucial factor in historically dense city neighborhoods.

- Easy Transport: Due to their relative lightness, they can usually be towed by standard commercial trucks, thus heavy haul permits and specialized transportation are not required, which significantly reduces mobilization costs between central urban jobsites.

- Indoor Capability: A lot of compact ranges, particularly those with electric or low-emission diesel engines, are feasible for basement excavation, interior demolition, and underground utility work where the air is not fresh.

The Core Advantage: Efficiency and Zero-Radius Turning

The mini skid steer loader’s steering system is its most distinguishing characteristic. Differential steering allows the left and right wheels (or tracks) to be done separately, thereby the machine can be turned around a point with a zero-degree radius.

This dexterity helps the operator to load, dump, and grade without much backing up or multi-point turns on a city road where every foot of space is essential. Skid steer mobility ensures the project steady forward motion, which is very important for the handling of large amounts of material in temporary staging areas or feeding garbage into a central dumpster.

- Precision Control: Contemporary hydraulic controls and joystick operation give the operators very detailed control, thus enabling them to make very small adjustments necessary for complicated tasks such as pavement cutting, trenching along building foundations, and sidewalk accurate grading.

- Optimized Cycle Times: The possibility of instant turning and pivoting greatly shortens the time that is needed for loading and dumping cycles, thus overall productivity figures are elevated which is very important for the compliance with strict city deadlines.

- Enhanced Visibility: The more recent compact skid steer loader models usually have vertically lifted booms and large cabin windows which give the operator better view around the machine’s perimeter and this is very important for the safe navigation of crowded urban jobsites that are also used by pedestrians and utility workers.

The Power of Versatility: Attachments as a Force Multiplier

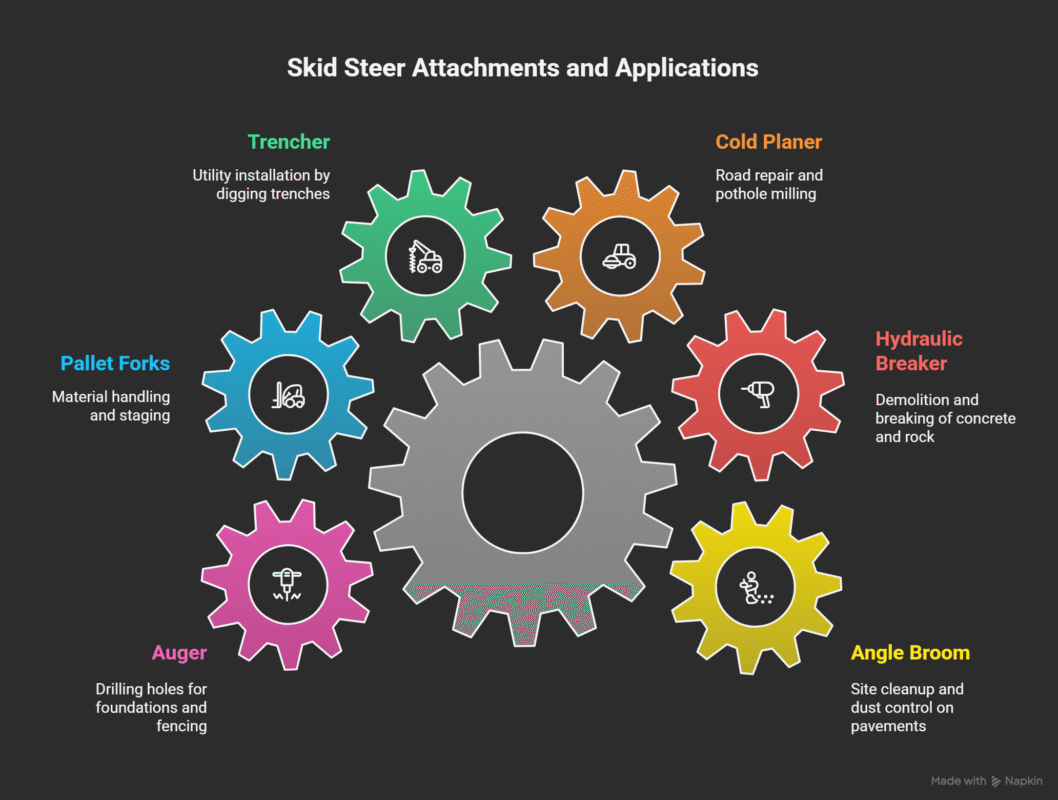

Although Skid steers are loaders, their compatibility with hundreds of hydraulic and mechanical attachments makes them the most valuable on urban work sites. This “Swiss Army knife” capability allows a single machine to transfer from one job to another i.e. from demolition to cleaning and finishing within minutes by using a universal quick-attach mechanism. It cuts down the number of on-site specialist equipment that’s needed thereby solving the problems of storage, transport, and scheduling.

Contractors who use a fleet of compact skid steer loaders can maximize usage and minimize equipment capital expenditure from breaking up concrete sidewalks to cleaning the street at night. The right skid steer attachments are what separate the movers of dirt from those who do intricate, precise jobs.

- Demolition and Breakout: With the help of attachments such as hydraulic hammers and concrete breakers, the compact machine can very quickly reduce the old structures and foundations to the fragments that it can handle, it is most of the time done inside the existing buildings.

- Finishing and Grading: By using precision instruments such as laser-guided box blades and land planes it is possible to produce perfectly smooth, accurate surfaces for paving, landscaping, and sidewalk installation which meet the stringent municipal specifications.

- Specialized Utility Work: Extremely specific attachments, e.g. augers for foundation piers and trenchers for the laying of utility lines, convert the loader into a digging specialist that is a must for underground infrastructure updates in densely populated metropolitan areas.

Essential Attachments for Urban Projects

The main factor for maximization of compact equipment efficiency is the correct attachment choice. The table below provides information on the common tools which are essential for the successful operations of urban jobsites:

| Skid Steer Attachments | Primary Urban Function | Target Material/Application |

| Angle Broom / Sweeper | Site Cleanup & Dust Control | Pavement, concrete, asphalt, general debris, snow |

| Hydraulic Breaker | Demolition & Breaking | Concrete slabs, asphalt, rock, brick walls |

| Cold Planer | Road Repair & Pothole Milling | Removing or milling small sections of asphalt or concrete |

| Trencher | Utility Installation | Digging narrow, deep trenches for cable, fiber, or water lines |

| Pallet Forks | Material Handling | Moving and staging bulk materials, pipe, and concrete forms |

| Auger | Foundation & Fencing | Drilling holes for fence posts, sign installation, or foundation piers |

Skid Steer Attachments Compact Skid Steer Loader urban construction- visual selection

Wheels vs. Tracks: Choosing the Right Undercarriage for Paved Surfaces

The choice of whether to use a wheeled skid steer loader (SSL) or a small Track Loader when deploying small equipment in a city is very important. A CTL has a better grip and less ground pressure on soft, muddy, or uneven terrain, however, urban worksite conditions are mostly more suitable for the wheeled skid steer.

SSL tires are good for use on asphalt, concrete, packed gravel, and walkways. Wheeled units are faster in between work zones or can carry material over a large paved area, and their undercarriage parts require less work than a CTLs’ complicated track system. Knowing SSL vs. CTL is a way to maximize performance and minimize overhead costs on urban projects.

- Pavement Performance: Wheeled skid steers have excellent traction and cause minimal surface damage when they are operated on hard, improved surfaces, which are the dominant conditions in developed urban areas.

- Maintenance Cost Reduction: While tires are subject to wear, they are significantly cheaper and faster to replace than rubber tracks, thus reducing the time that the machine cannot be used and also lowering the long-term total cost of ownership in places with high rates of abrasion such as concrete and asphalt.

- Radial vs Vertical Lift: The decision between Radial vs Vertical Lift paths is also influenced by the factor. Even though vertical lift arms can be used to load high-sided dump trucks as they provide a higher reach, radial lift designs are mostly simpler, more compact, and better suited for ground-engaging work such as digging and grading—which are the tasks that are frequently done in urban utility and site-prep applications.

Efficiency, Safety, and the Bottom Line in Congested Spaces

Compact skid steer loaders are not only good for mobility but they also enhance project budget, timetable, and site safety. Due to expensive permission fees and time-of-day constraints, any reduction in labor or time which takes place in very busy metropolitan settings results in money being saved straight away.

By the use of one adaptable loader, contractors save fuel, operator training, and on-site staff by integrating many single-task machines into one. Smaller and quieter machines that are working close to the public are safer for the workers and city residents.

- Fuel and Emission Savings: Small engines normally consume less fuel than their full-sized counterparts, thus the operating expenditures are lowered, and newly installed Tier 4 Final/Stage V compliant engines or electric models further lessen the environmental impact and are in line with the more and more stringent city emission standards.

- Logistical Simplicity: The compact skid steer loader inherent ease of use greatly facilitates the scheduling, by reducing the number of equipment spotters that are needed, and by dramatically cutting the storage space that is required at a very expensive urban jobsite.

- Noise Reduction: Several municipalities put severe limitations on the noise made at night or in residential areas; the smaller and quieter operation of the compact loaders, especially the new electric models, makes it possible to have more working hours, thus the project milestones are achieved without any disruption of the local community.

The Future is Quiet: Electric and High-Tech Compact Skid Steer Loaders

The compact skid steer loader transformation is getting faster, mostly because of the need for very efficient and environmentally friendly operations in dense areas. The most recent loaders generation is equipped with the advanced technologies mainly focused on automation and electrification, thus the future holds a radical change in urban jobsite management.

To a large extent, all-electric skid steers are very attractive; their non-polluting footprint along with the almost-silent mode of operation, are the answers to the two biggest problems that are at the top of the list of restrictions for the contractors in the cities: the air quality and noise regulations. Besides that, the use of telematics, GPS, and semi-autonomous controls is the next step pushing the limits of these small machines, thus they become safer and more productive though space is very limited.

- Zero-Emission Operation: Electric SSLs are the perfect choice for sensitive indoor demolition, warehouse work, and subterranean projects where the presence of diesel fumes is not allowed, thus substantially widening the range of machine applications.

- Telematics and Diagnostics: Inbuilt technology offers real-time information on machine condition, location, and usage, thus allowing fleet managers to optimize deployment and plan preventative maintenance in an efficient way, thus cutting the downtime that was not previously scheduled.

- Automated Controls: Self-leveling loader arms and grade control systems are some of the features that lead to automation and they facilitate the accuracy while at the same time, lessen the operator’s tiredness, thus a smaller crew can accomplish higher volumes of earthmoving and grading work with the same level of accuracy.

Conclusion: The Indispensable City Workhorse

Constant urban construction development calls for intelligent and special solutions to the problems of limited space, tight deadlines, and strict environmental requirements. The mini skid steer loader is a perfect answer to the logistic and operational challenges of the city.

Thanks to its core skid steer mobility, which makes it able to turn within its footprint, and its high compatibility with numerous skid steer accessories, this machine behaves like big equipment but in a light package.

In a densely populated metropolitan cores, compact skid steer loaders will always be the key machines of the urban construction businesses which are after maximum compact equipment efficiency and profitability. To become skilled in the use of urban worksite, the first step is the correct model choice—taking into account lift type, wheel/track selection, and hydraulic flow.

FAQs on Urban Construction – Compact Skid Steer Loaders

What is the difference between a Skid Steer Loader (SSL) and a Compact Track Loader (CTL)?

Wheeled SSLs (Skid Steer Loaders) are more suitable for use on concrete and asphalt in cities. They are also quicker and cheaper to buy and maintain.

While CTLs (Compact Track Loaders) with rubber tracks are good for soft, unstable, or uneven terrains because of their better flotation and lower ground pressure.

How do I choose between a Radial Lift and a Vertical Lift skid steer?

Radial Lift: The arm shape is/was made better for digging and moving dirt. Their simplicity and lower price are usually the better ones.

Vertical Lift: It is the best for loading high-sided dump trucks or stacking material, the arm keeps the load more uniform throughout the lift cycle and also at the maximum height the reach is higher.

What is the minimum Rated Operating Capacity (ROC) I need for a city project?

The ROC is defined by the weight when one is lifting concrete slabs or full buckets of debris. Urban utility and material handling machines usually have a minimum ROC of 1,750 lbs (800 kg), whereas large-frame loaders may go up to 2,500 lbs for higher lifts.

Are electric skid steer loaders a viable option for urban jobsites?

Certainly, the answer is yes. Electric SSLs are the perfect indoor tasks, late-night utility projects, and works in densely populated residential areas with tight noise and air quality restrictions because they have zero emissions and are quieter. Their performance is on a par with diesels.

What is the most important hydraulic feature for attachment compatibility?

Standard Flow low-flow hydraulics can operate a bucket and a fork; however, High-Flow systems (usually > 30 GPM) are required for the power of high-production urban equipment like cold planers, asphalt grinders, mulchers, and large trenchers.

Can I transport a compact skid steer with a standard pickup truck and trailer?

Variations of large SSL may attempt loads that are beyond the capacity of consumer trucks. The majority of medium-frame and all micro skid steers are light enough (operational weight ranges from 2,500 to 7,500 lbs) to be safely transported by a heavy-duty pickup truck and a dual-axle equipment trailer thus cutting down the expenses of specialist transportation.

How often should I replace the tires on my wheeled skid steer loader?

The lifespan of tires is highly dependent on the type of surface and the way they are used. The life of tires can be as short as 600-800 hours when used on concrete and asphalt. Several urban contractors have opted for the installation of severe-duty solid rubber or foam-filled tires so as to protect against punctures and to increase their working time.